Tunnel - Ultrasonic Surface Waves (USW)

Target of Investigation

Ultrasonic surface wave (USW) testing has the following applications:(1)

- Measuring modulus of elasticity of the concrete.(2)

- Estimating strength of concrete using the correlation between strength and modulus.(3)

- Indirectly assessing delamination, honeycombing, and debonding in the surface course material.(4)

- Assessing conditions of concrete for damage from various causes, including alkali–silica reactions, fires, freeze–thaw cycles, and other cracking processes.(5)

Description

The USW technique is an offshoot of the spectral analysis of surface waves (SASW) method used in evaluating material properties (e.g., elastic moduli) in the area very near the surface. SASW uses surface-wave dispersion (i.e., velocity of propagation as a function of frequency and wavelength) in layered systems to obtain information about layer thickness and elastic moduli.(7) USW testing is identical to SASW testing except that the frequency range of interest is limited to a narrow high-frequency range in which the phase velocities of surface waves do not vary significantly with frequency. Using either the measured or assumed mass density and Poisson’s ratio of the material, the phase velocity can be converted to the material modulus. A USW test consists of recording the response of the deck at two receiver locations from an impact on the surface of the deck. USW testing equipment is shown in figure 1.

Figure 1. Photo. USW testing equipment.

Physical Principle

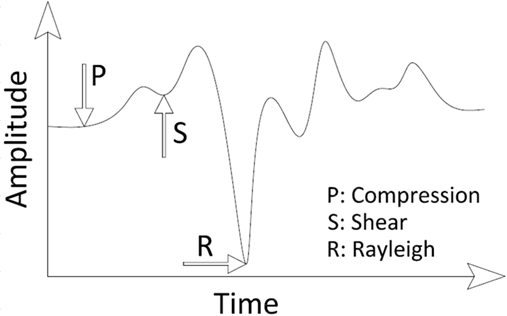

Surface waves are elastic waves that travel along the free surface of a material and, in most cases, constitute the predominant proportion of energy in comparison to body waves, such as compressive waves (P-waves) and shear waves (S-waves).(7) The arrival of the surface (Rayleigh) wave follows the arrival of the two body-wave components because the surface wave is slower (figure 2).

Figure 2. Graph. Typical time record obtained from USW testing.(7)

Surface waves propagate radially from the impact source, forming a cylindrical front with a velocity dependent on the elastic properties of the medium. The waves propagating in a layered medium are dispersive; that is, waves of different wavelengths or frequencies travel with different velocities. Thus, information about the subsurface can be obtained by measuring the phase velocity versus frequency (dispersion curve) and backcalculating the dispersion curve to obtain the profile of the tested system (layer thickness and modulus).

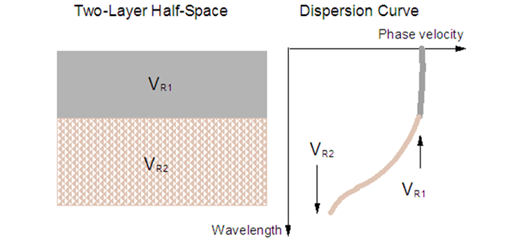

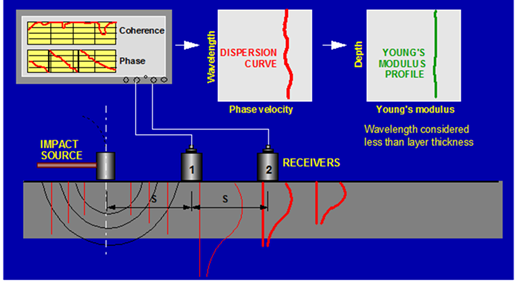

Surface-wave energy extends to a depth of approximately one wavelength. At wavelengths less than or equal to the thickness of the layer, the velocity of surface-wave propagation is more or less independent of wavelength (figure 3 and figure 4). Therefore, if the measurement is limited to wavelengths not exceeding the thickness of the surface course, the velocity of surface waves will be dependent only on the modulus of the surface course material. An average velocity is used for correlating to the material modulus. Significant variation in the phase velocity indicates the presence of delamination or another anomaly.(8)

VR1 and VR2: Rayleigh wave velocities in a two-layer half space.

Figure 3. Illustration. Phase velocity versus wavelength.(7)

S: Distance between impactor and receiver.

Figure 4. Illustration. Evaluation of a layer modulus through USW testing.(7)

Data Acquisition

The basic components of USW equipment include a source, at least one pair of receivers, and a portable computer with data acquisition software.(4) USW equipment enables both automatic and semiautomatic data collection and processing. Figure 5 shows an example of a simple USW device (a portable seismic property analyzer) with a solenoid-type impact source and two receivers (accelerometers). Once the device is placed on the ground, a series of impacts from the source is detected by the receiver pair and recorded on a portable computer.

Figure 5. Photo. USW testing using a portable seismic property analyzer in a cart.

Data Processing

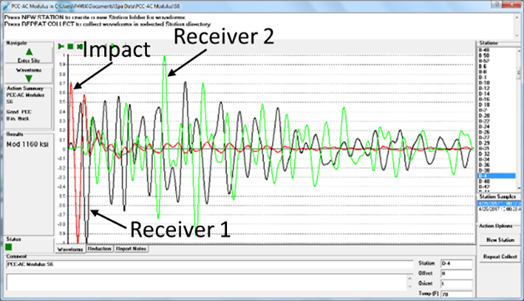

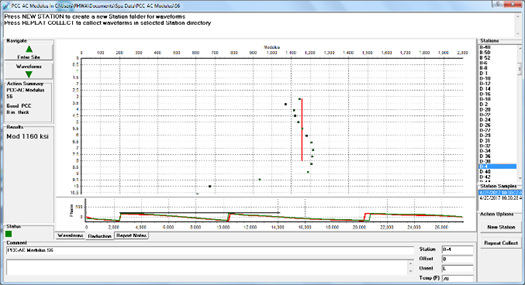

Compressional waves arrive at the receivers first and are followed by shear waves and then surface waves.(3) However, more than two-thirds of the energy in the wave train is in the surface waves, making them more easily recorded. Figure 3 and figure 4 illustrate the data-processing procedure of SASW testing. A dynamic signal analyzer is used to transform the receiver outputs from the time domain to the frequency domain. The coherence function and phase difference between the two receivers are acquired. The coherence function is a measure of the degree by which the signals are linearly correlated. The cross-power spectrum is used to obtain the relative phase shift between two signals (two-channel recorder). The received signals are processed, and a subsequent calculation scheme is used to calculate the modulus directly in the field (figure 6).

A. Raw data.

B. Processed data.

Figure 6. Screenshots. Raw and processed data during data collection.

Data Interpretation

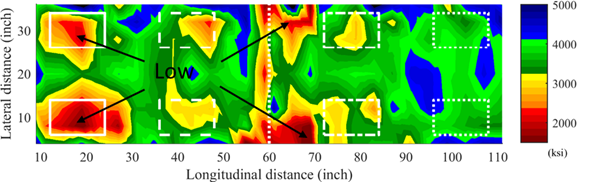

Data from USW testing are typically presented in terms of concrete modulus distribution (figure 7). A very low modulus often indicates low-quality material or the presence of delamination or cracking and does not necessarily represent the actual concrete modulus at the test location.

1 inch = 2.54 cm; 1 ksi = 6.9 mPa.

Figure 7. Contour map. Concrete modulus distribution from USW testing.

Advantages

Advantages of USW testing include the following:

- Repeatability.

- Determination of modulus of material for appropriate design.

Limitations

Limitations of USW testing include the following:

- Slow data collection.

- Tunnel and bridge closures necessary.

- Expertise and training required for equipment setup and data collection, processing, and interpretation.

- Complicated backcalculation for multilayer systems.

- Limited ability to provide the degree of severity.

- Inability to measure concrete condition below the top of the discontinuity.(6)

References

- Olson Engineering. (2018). “Spectral Analysis of Surface Waves.” (website) Olson Engineering, Wheat Ridge, CO. Available online: http://www.olsonengineering.com/methods/structural-pavement-tunnel-methods/spectral-analysis-of-surface-waves/, last accessed March 12, 2019.

- Nazarian, S., Baker, M., and Crain, K. (1997). “Assessing quality of concrete with wave propagation techniques.” ACI Materials Journal, 94(4), pp. 296–305, American Concrete Institute, Farmington Hills, MI.

- Nazarian, S., Yuan, D., Smith, K., Ansari, F., and Gonzalez, C. (2006). Acceptance Criteria of Airfield Concrete Pavement Using Seismic and Maturity Concepts, Report No. IPRF-01-G-002-02-2, Federal Aviation Administration, Washington, DC.

- Gucunski, N., Imani, A., Romero, F., Nazarian, S., Yuan, D., Wiggenhauser, H., Shokouhi, P., Taffee, A., and Kutrubes, D. (2013). Nondestructive Testing to Identify Concrete Bridge Deck Deterioration, Report No. S2-R06A-RR-1, Transportation Research Board, Washington, DC

- Azari, H. and Nazarian, S. (2016). “Assessment of Concrete Structures Impacted by Alkali-Silica Reaction and Freeze-Thaw by Use of Ultrasonic Surface Wave Method.” Transportation Research Record, 2592, pp. 117–125, Transportation Research Board, Washington, DC.

- Heitzman, M., Maser, K., Tran, N.H., Brown, T., Bell, H., Holland, S., Ceylan, H., Belli, K., and Hiltunen, D. (2013). Nondestructive Testing to Identify Delaminations Between HMA Layers, Report No. S2-R06D-RR-1, Transportation Research Board, Washington, DC.

- Gucunski, N., Romero F., Kruschwitz, S., Feldmann, R., Parvardeh H. (2011). Comprehensive Bridge Deck Deterioration Mapping of Nine Bridges by Nondestructive Evaluation Technologies, Report No. SPR-NDEB(90)–8H-00, Iowa Highway Research Board, Ames, IA.

- Lin, S. (2014). Advancements in active surface wave methods: modeling, testing, and inversion, Ph.D. dissertation, Iowa State University, Ames, IA.