Pavements - Traffic Speed Deflection Devices (TSDDs)

Target of Investigation

Traffic speed deflection devices (TSDDs) can assess the structural condition of pavement at a network level. They can help identify potentially damaged areas and provide targets for further detailed inspection and testing. TSDDs can be used for multiple applications, such as the following:

- Identifying weak sections of road surfaces.

- Detecting damage, such as delamination and voids.

- Estimating effective structural number (SNeff) which is an indicator of structural capacity of in-service pavement sections.

- Evaluating concrete pavement joints.

Description

Several organizations in the United States and Europe have developed TSDDs over the past several decades that can continuously measure pavement deflections at posted traffic speeds (up to 95 km/h [60 mi/h]).(1) The commonly used TSDDs is the traffic speed deflectometer (TSD). The TSD is an articulated truck with a variable rear axle load, typically 80 kN (18 kips). It employs a series of Doppler-shift lasers to measure the velocity and slope of the deflecting road surface. The processed TSD measurements produce continuous profiles of deflection and deflection slope.(2) The TSD can test approximately 300–500 lane-km (200–300 lane-mi) per day. A TSD is shown in figure 1.

© 2018 ARRB.

© 2018 ARRB.Physical Principle

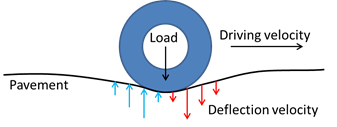

deflection velocity of a loaded pavement.(2,4) The Doppler lasers are positioned such that they measure deflection velocity at a range of distances in front of the rear axle. For example, a TSD prototype had sensors at 4, 8, and 12 inches (100, 200, and 300 mm) in front of the rear axle to measure the deflection bowl, and another sensor at 3,600 mm (30 inches) from the rear axle to work as a reference outside the deflection bowl.(2) The Greenwood TSD 7 had sensors at 4, 8, 12, 15, 20, and 30 inches (100; 200; 300; 450; 600; 900; and 3,500 mm) ahead of the rear axle.(4) The beam on which the lasers are mounted moves up and down in opposition to the movement of the trailer in order to keep the lasers at a constant height from the pavement surface. To prevent thermal distortion of the steel measurement beam, a climate-control system maintains the trailer temperature at a constant 68℉ (20℃).(2) TSDs measure the vertical direction velocity of the pavement under a given load and integrate the velocity to get the deflection curve.

The sensors of the Doppler lasers measure the deflection velocity of the pavement. The deflection of the pavement under a moving wheel load is illustrated in figure 2.

Source: FHWA.

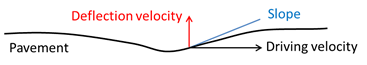

Source: FHWA.The deflection slope is deflection velocity divided by vehicle velocity (figure 3 and figure 4). Because the slope of deflection is the derivative of displacement, the displacement of the pavement can then be determined. Data are recorded at a survey speed of up to 50 mi/h (80 km/h) at a rate of 1,000 Hz (i.e., a 0.8-inch [20-mm] spacing of the raw measurements). These results are usually reported as averages over 33-ft (10-m) sections.

- Where:

- slope = deflection slope.

- vdeflection = deflection velocity.

- vvehicle = vehicle velocity.

Source: FHWA.

Source: FHWA.More sensors with different frequencies and spacing are being applied on newer versions of TSDs.

Data Acquisition

Data are automatically collected and stored by TSD system at traffic speed.

Data Processing

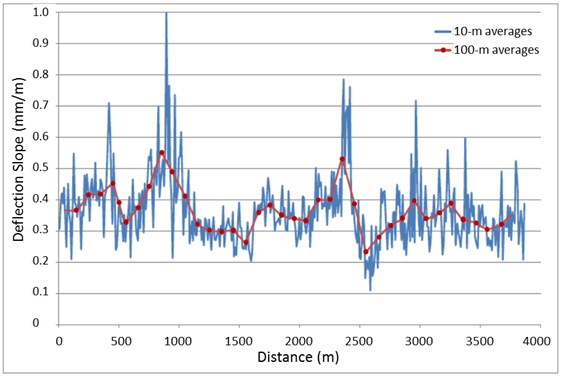

The raw data collected by each sensor may contain undesirable noise. The common procedure with TSD data has been to determine an average over 33-ft (10-m) intervals.(2) Bearing-capacity characteristics can also be estimated based on deflection slopes. These include the center deflection and the surface curvature index SCI300, which equals the difference of the deflection at its center and the deflection at 12 inches (300 mm) from the center.

Data Interpretation

TSD results can be presented in a table or a profile graph. Postprocessed TSD results are presented in terms of deflection slopes. Low and uniform deflections or deflection slopes indicate good uniformity and structural conditions, while high and variable deflections or deflection slopes indicate poor conditions. Figure 5 is a TSD deflection-slope profile.

© 2012 TRB.1 m = 3.3 ft;1 mm= 0.039 inches.

© 2012 TRB.1 m = 3.3 ft;1 mm= 0.039 inches.Advantages

Advantages of TSDDs include the following:

- Collects pavement condition and structural parameters in one pass.

- Operates at traffic speed.

- Increases operator and road-user safety.

- Offers more continuous data measurements than traditional methods such as falling weight deflectometers (discrete).

- Requires no traffic control, making it cost efficient.

- Allows flexibility in survey planning and network coverage.

Limitations

Limitations of TSDDs include the following:

- Data need spatial averaging for usable accuracy.(4)

- Results affected by temperature; correction is needed.(5)

References

- Rada, G., Nazarian, S., Visintine, B., Siddharthan, R.V., and Thyagarajan, S. (2016). Pavement Structural Evaluation at the Network Level, Report No. FHWA-HRT-15-074. Federal Highway Administration, Washington, DC.

- Flintsch, G., Ferne, B., Diefenderfer, B., Katicha, S., Bryce, J., Nell, S., and Clark, T. (2012). Assessment of Continuous Pavement Deflection Measuring Technologies, Report No. SHRP 2 R06(F), Transportation Research Board, Washington, DC.

- Australian Road Research Board. (2018). “Intelligent Pavement Assessment Vehicle: iPAVe.” (website) New South Wales, Australia. Available online: https://www.arrb.com.au/ipave, last accessed June 29, 2018.

- Applied Research Associates, Inc. (2007). Rolling Wheel Deflectometer (RWD) Demonstration for the Oregon Department of Transportation (ODOT) Final Report, Oregon Department of Transportation, Salem, OR.

- Federal Highway Administration. (2005). “Rolling wheel deflectometer testing on the Natchez Trace Parkway.” (website) Washington, DC. Available online: https://www.fhwa.dot.gov/pavement/management/rwd/nt/appa.cfm, last accessed March 6, 2019.