Pavements - Straightedge (SE)

Target of Investigation

A straightedge is employed to measure the magnitude of rutting on asphalt roadways.

Description

Rutting is vertical depression along the wheelpath of a road surface. Rutting of an asphalt road in a tunnel is usually caused by permanent deformation of the road surface under the traffic load. Ruts filled with water can cause hydroplaning. They can also affect ride quality when a vehicle is moving laterally in a lane or changing lanes because ruts tend to pull the vehicle toward the rut path. A straightedge (figure 1) can be used to measure the magnitude of rutting in millimeters, so that action can be taken when the rut depth exceeds a certain level.

Source: FHWA.

Source: FHWA.Physical Principle

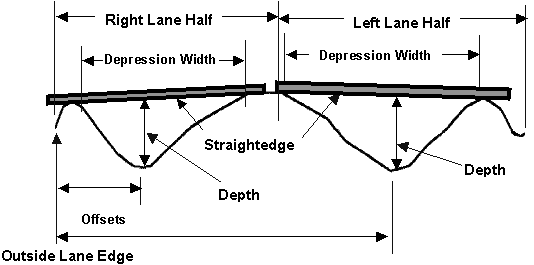

The common method of measuring the magnitude of rutting is to place a 3- to 4-ft (0.9- to 1.2-m) straightedge across the wheelpath to measure its maximum rut depth. The straightedge works as a reference (figure 2). A tape measure (or ruler) is used to measure the maximum vertical distance between the road surface and the straightedge. The straightedge should be positioned at various locations on each half of the lane until the maximum displacement is found.

Source: FHWA.

Source: FHWA.Data Acquisition

ASTM E1703/E1703M, Standard Test Method for Measuring Rut-Depth of Pavement Surfaces Using a Straightedge, lists the procedures for using the straightedge to measure rut depth.(3) The straightedge is placed across the rut in a plane perpendicular to the direction of traffic movement. The straightedge is allowed to rest upon the road surface at two contact areas such that sliding the straightedge along its length in both directions does not change the contact areas on the road surface. The bottom surface of the straightedge should be parallel to the longitudinal slope of the roadway. The measuring gauge is placed perpendicular to the reference plane created by the bottom of the straightedge and perpendicular to the longitudinal slope of the roadway. The bottom of the gauge should be in contact with the road surface at the time of measurement. The straightedge or gauge should not be placed on any discontinuities, such as potholes or loose debris. After the gauge has been placed, the distance between the bottom surface of the straightedge and the road surface is measured. A sufficient number of measurements should be made along the straightedge to determine the greatest distance between the straightedge and the road surface. Greater intervals between successive straightedge placements produce less precise results.

Data Processing

Little data processing is needed. Statistical analysis can be performed for the road segment to decide if corrective actions are needed.

Data Interpretation

The data are usually presented in tabular format. A large rut depth indicates heavy distress. The rut-depth profile could also be presented in a graph.

Advantages

Advantages of straightedges include the following:

- Low-cost equipment.

- Simple data collection and processing.

Limitations

Limitations of straightedges include the following:

- Measurement is not continuous along the road.

- Traffic control and lane closure may be required.

References

- Miller, J.S. and Bellinger, W.Y. (2014). Distress Identification Manual for the Long-Term Pavement Performance Program, Report No. FHWA-HRT-13-092, Federal Highway Administration, Washington, DC.

- Elkins, G.E., Schmalzer, P., Thompson, T., and Simpson, A. (2003). Long-Term Pavement Performance Information Management System Pavement Performance Database User Guide, Report No. FHWA-RD-03-088, Federal Highway Administration, Washington, DC.

- ASTM E1703/E1703M-10. (2015). “Standard Test Method for Measuring Rut-Depth of Pavement Surfaces Using a Straightedge.” Book of Standards 04.03, ASTM International, West Conshohocken, PA.