Bridge - Screw Withdrawal Testing

Target of investigations

Screw withdrawal testing has been developed to assess the biological deterioration (i.e., fungal decay) in wood members.(1)

Description

Screw withdrawal testing aims to provide information about the wood’s physical and mechanical properties by measuring the maximum load required to pull out the screw.

Physical Principle

Because wood biologically deteriorates, it tends to soften and experience a reduction in specific gravity. Thus, it shows less resistance against screw withdrawal.

Data Acquisition

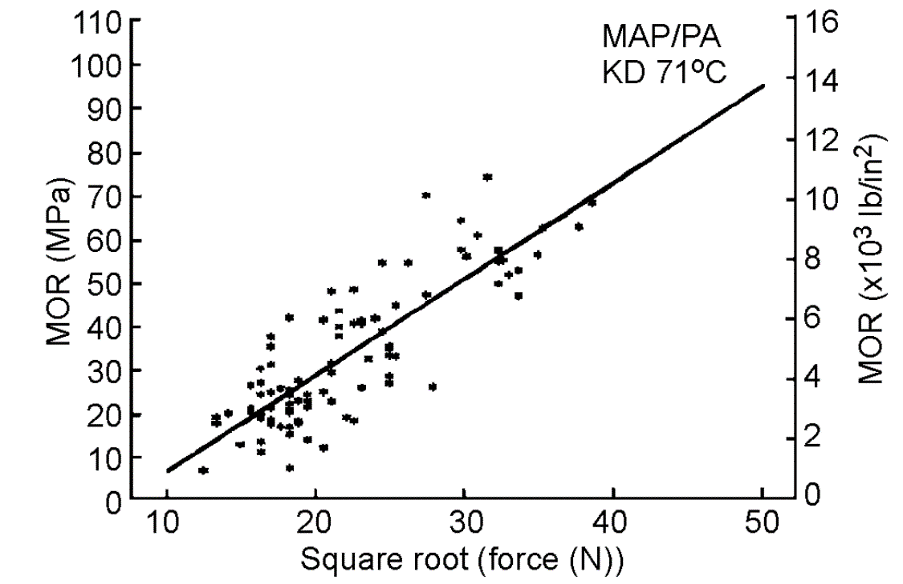

To measure the withdrawal resistance, first, a screw is driven perpendicular to the wood surface, and the force used to pull out the screw is recorded. The withdrawal resistance is related to the density, modulus of elasticity, modulus of rupture, and shear modulus. (figure 1).(1) While the screw withdrawal results are mainly affected by the local properties of a wood member, results from the sound and deteriorated locations can help evaluate the condition of timber structures such as bridges.

A. A commercial screw withdrawal resistance unit.

KD = kiln-dried; MAP = monoammonium phosphate; MOR = modulus of rupture;

MPa = megapascals; PA = phosphoric acid.

B. Correlation between the square root of withdrawal force and bending strength (modulus of rupture) for 12-mm (0.5-inch) thick plywood kiln-dried at 71℃ and treated with fire retardant preservatives (monoammonium phosphate, phosphoric acid).(1)

Figure 1. Photo and scatter plot. Measuring the withdrawal resistance.

Data Processing

No data processing is required

Data Interpretation

No data interpretation is required

Advantages

Density, modulus of elasticity, modulus of rupture, and shear modulus are correlated to screw withdrawal values

Limitations

Limitations of screw withdrawal testing include the following:

- Information about local wood properties is provided.

- Number of tests is often limited.

- Additional testing or a database with a standardized instrument is required to correlate the withdrawal resistance to physical and mechanical properties of wood.(2)

- Test results affected by in situ properties of wood, such as moisture content.(2)

References

- White, R. H., and R. J. Ross, eds. 2014. Wood and Timber Condition Assessment Manual. 2nd ed. General Technical Report No. FPL-GTR-234. Madison, WI: U.S. Department of Agriculture, Forest Service, Forest Products Laboratory.

- Riggio, M., R. W. Anthony, F. Augelli, B. Kasal, T. Lechner, W. Muller, and T. Tanner. 2014. “In Situ Assessment of Structural Timber Using Non-Destructive Techniques.” Materials and Structures 47, no. 5: 749–766.