Pavements - Sand Patch Test (SPT)

Target of Investigation

Pavement surface texture influences many different pavement–tire interactions and can impact noise, drainage, ride quality, and safety.(1) The sand patch test is employed to measure the texture of the pavement surface.

Description

Texture wavelengths affect various pavement–tire interactions, including friction, interior and exterior noise, splash and spray, rolling resistance, and tire wear.(2) The sand patch test is a field test that uses a volumetric approach to determine the average macrotexture depth of a pavement surface. A known volume of sand is spread evenly over the pavement surface to form a circle. The diameter of the circle is measured on four axes and the values are averaged (figure 1). This value is then used to calculate the mean texture depth (MTD).

Source: FHWA.

Source: FHWA.Physical Principle

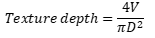

In the sand patch test, the apertures between aggregates are filled with sand (figure 2). Assuming the sand is distributed in the pavement as a cylinder, the average texture depth can be calculated with the volume and area of the top surface of the cylinder. The equation for calculating average texture depth is given in figure 3. V is the volume of sand used in millimeters cubed (inches cubed). D is the average diameter of the sand patch circle in millimeters (inches).

Source: FHWA.

Source: FHWA.

Data Acquisition

The procedure for performing the sand patch test can be found in ASTM E965-15, Standard Test Method for Measuring Pavement Macrotexture Depth Using a Volumetric Technique.(4) The pavement surface is cleared of debris by sweeping the surface with a small brush. The test area is clear of cracking, and the pavement area must be dry. A known volume of sand is measured and then, using a measuring cylinder, poured onto the road surface to form a cone. The sand is spread with a spreading disc to form a circular patch. Horizontal forces are applied to the spreading disc and worked outward in a circular pattern until the surface depressions are filled to the level of the peaks. The sand is to be used only once. The diameter is measured at four different angles by rotating 45 degrees between each measurement.(2) The mean diameter is recorded.

Data Processing

Not much data processing is needed. The MTD is calculated by plugging the known sand volume and the average diameter of the sand disc into the equation in figure 3.

Data Interpretation

Data are usually presented in tabular format. A large MTD means a large size for the macrotexture of the pavement surface.

Advantages

Advantages of sand patch tests include the following:

- Test procedure is simple.

- Result is of high certainty.

Limitations

Limitations of sand patch tests include the following:

- Test cannot be performed continuously for the pavement but must be performed at each individual test location, which can be a slow process.

- Traffic control and lane closure may be required.

References

- Hibbs, B.O. and Larson, R.M. (1996). Tire Pavement Noise and Safety Performance, PCC Surface Texture Technical Working Group, Report No. FHWA-SA-96-068, Federal Highway Administration, Washington, DC.

- Minnesota Department of Transportation. (2010). Texture–Sand Patch, Version 2, MnDOT, Saint Paul, MN. Available online: http://www.dot.state.mn.us/mnroad/data/pdfs/MnROAD%20Texture%20Sand%20Patch%20FINAL_062410.pdf, last accessed February 28, 2019.

- Federal Highway Administration. (1996). “Research & Technology Transporter.” (website) Washington, DC. Available online: https://www.fhwa.dot.gov/publications/transporter/96oct/index.cfm, last accessed February 2, 2019.

- ASTM E965-15. (2015). “Standard Test Method for Measuring Pavement Macrotexture Depth Using a Volumetric Technique.” Book of Standards 04.03, ASTM International, West Conshohocken, PA.