Bridge - Radiography (RAD Tendons)

Target of Investigation

Radiography can be used for the following applications:

- Determining the positions, diameters, and condition of tendons and strands in post-tensioned and prestressed concrete girders.

- Detecting voids in cast-in-place, precast prestressed concrete girders.

- Assessing the grouting condition in the post-tensioning ducts.

Description

Concrete radiography is similar to radiography used to produce medical x rays. This method involves gaining information in a test object by subjecting it to high energy electromagnetic radiation. The propagation of radiation through the test object is captured on a special photographic film on the opposite side of the specimen to produce a photograph like representation of the internal structure of the concrete.

Physical Principle

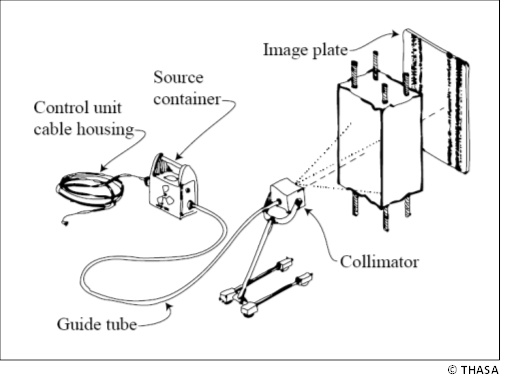

The basic concept of gamma-ray radiography is illustrated in figure 1. A source transfers gamma-ray energy to a collimator through a guide tube by means of a telecontrol unit so that gamma rays impinge on the sample to be inspected. On the other side of the sample, an image plate registers the gamma-ray intensity traversing the sample. The lower the density of the material is, the higher the intensity of the gamma-ray energy that reaches the plate will be.

Since concrete is about 2.5 times denser than biological tissues, x rays used in medicine are not suitable for concrete members. For this reason, concrete radiography usually employs gamma-ray sources instead of x-ray generators such as are used in medicine. Another advantage of gamma rays over x rays is gamma rays are emitted spontaneously by certain substances so electrical power is not required. An additional advantage of the 192Ir source is it can be housed in a small and relatively light container (~ 20 kg, 44lb).

The penetration of the gamma ray energy depends on its wavelength and energy level. The higher the source energy is, the greater the penetration of the gamma ray energy will be.

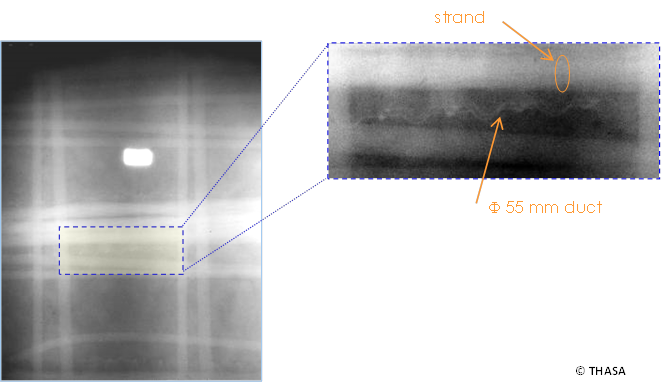

Figure 2 shows how voids are readily identified by using the radiographic method. An empty soda bottle embedded in a concrete block irradiated with gamma rays from a 192Ir source can be readily identified. The attenuation produced by voids (air) is negligible. Hence radiation transmitted through a void in the interior of a concrete sample will produce a “shadow” darker than the areas where radiation traverses the full thickness of the concrete sample.

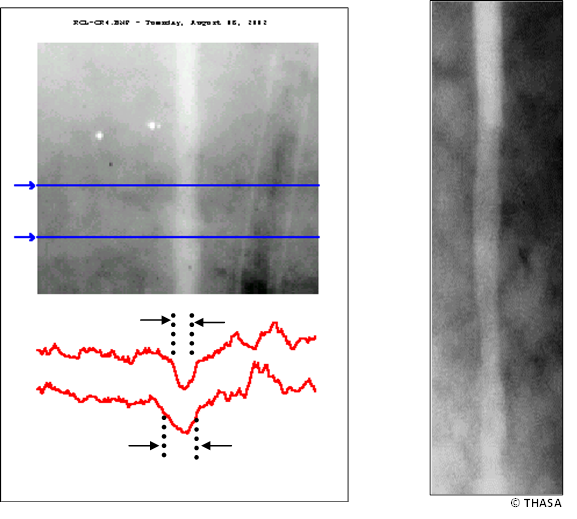

Since steel attenuates gamma ray energy more than concrete, steel elements such as rebars or strands embedded in a concrete sample project a lighter “shadow” on the image plate. A severely corroded rebar with a nonuniform cross section projects on the image plate non-uniformly (figure 3). These are radiographs of a slab (left) and a tank wall (right) obtained with a 192Ir source. The radiograph on the left hand side also shows an electrical conduit to the right of a corroded rebar. The red lines in the lower part display the photographic density along the “cuts,” indicated by the blue lines on the radiograph. They help visualize the reduced cross section due to corrosion.

Data Acquisition

Image plates, either conventional or more modern computed radiography (CR) image plates, record the gamma ray energy penetrated to the opposite side of a sample emitted from a 192Ir, 137Cs, or 60Co source. Conventional image plates must be developed after exposure, while CR image plates are converted into digitized images. The recording resolution of the CR image plates is about 5 times greater than that of conventional image plates. Plate size is usually 35 cm by 43 cm (14 inches by 17 inches).

Data Processing

Figure 4 shows the detail obtained in an inspection done with the radiographic method of a post-tensioned box girder.(1) The horizontal band near the center is a post-tensioned cable. The impression of the duct can be seen in the insert. The other white lines in the right picture correspond to ordinary reinforcement, while the white rectangle is an external reference. These pictures show that this method is an appropriate tool for studying profiles of cables and ducts in post-tensioned and precast prestressed concrete girders. The quantitative determination of profiling defects is discussed below.

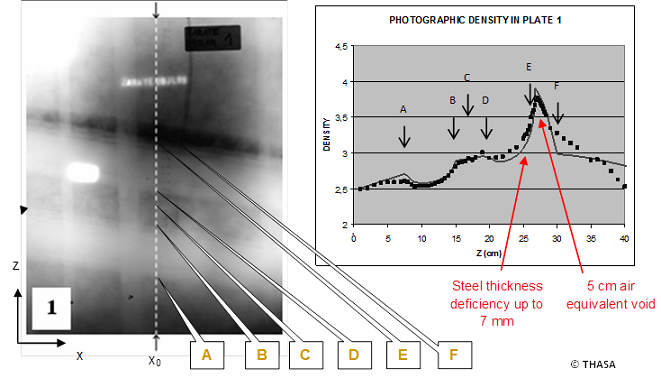

In the case of traditional radiographic methods where the image plates are film, the recorded data are the photographic density values at each point of the plate. The density is determined by measuring the intensity of the light transmitted through the plate when the plate is illuminated from the opposite side with a light source of constant and uniform intensity. The density is then compared with the expected value for a given configuration using a least squares fitting procedure to determine the profile of the tendon and the nature and extension of defects in the tendons as illustrated in figure 4. In the case of CR image plates, the gray level of each pixel is equivalent to density.

Data Interpretation

Figure 5 shows an example of profiling tendons in post-tensioned concrete girders using film radiography. The girder contains two ducts, one of them having a severe grouting defect.(2) The data interpretation involves examining the density D(xo,z), where xo is the x-coordinate of the vertical dotted line in the radiograph in figure 5. The data points in the plot on the right hand side of figure 5 are the values of D(xo,z).

In the right figure, the “bowl” shapes in the intervals A-B and D-E correspond to the cables. The “peak density,” corresponding to the dark band above the cable in the upper duct, is the manifestation of a void in this duct. The thin line in the right plot corresponds to the calculated density values.

The parameters in red were adjusted to fit the data. The positions and diameters of cables and ducts were obtained from the measured data and by tomographic analysis. The obtained value of the “void” density determines the depth of the void as 5 cm air equivalent, and the small difference between the measured and calculated D values in the interval D-E may be an indication that the cable section is reduced by up to about 7 mm.

Advantages

- Produces “photographic” quality results and precise locating of reinforcement for condition assessment, void detection, and grout condition assessment.

- Small, portable source systems.

- Some source systems, such as those employed with 192Ir source, are easy to shield and Can be used in the field without interrupting traffic or causing disturbances to the general public.

Limitations

- Requires precautionary measures against gamma rays. Public exposure to radiations must always be below the limits set by the Nuclear Regulatory Commission and State regulations.

- Small, portable gamma ray source systems can only penetrate concrete elements of the thickness up to about 300 mm. Systems that can emit more energy must be used for thicker elements.

References

- Pimentel, M., et. al., “Gamma-Ray Inspection of Post Tensioning Cables in a Concrete Bridge,” Structural Faults and Repair 2010, 13th International Conference, Edinburgh, June 2010.

- Mariscotti, M.A.J., et. al., “Gamma-Ray Imaging for Void and Corrosion Assessment,” Concrete International, Vol. 31, No. 11, November 2009, pp.48-53.

- The data shown in this article are taken from studies carried out by THASA (www.thasa.com).