Tunnel - Pulsed Eddy-Current Testing (PECT)

Target of Investigation

Pulsed eddy-current testing (PECT) can be used to measure the thicknesses of and detect defects and corrosion in steel members without the removal of insulation and coatings.

Description

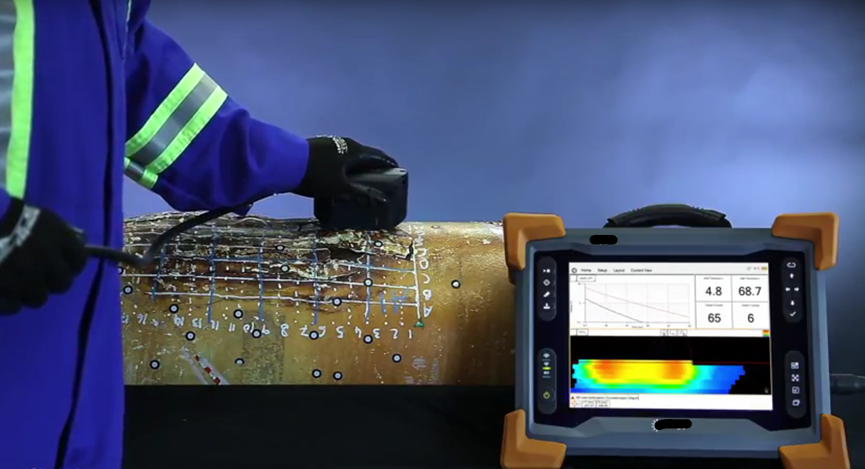

PECT is based on the principle of electromagnetic induction. Unlike eddy current testing (ECT), which uses a single frequency sinusoidal excitation, PECT employs a rectangle pulse excitation in the primary coil. Time-domain analysis is conducted for the voltage pulse received by the testing coil.(1) Eddy currents are induced in the specimen by the rising and falling of the excitation pulse. The frequency spectrum of the excitation signal of PECT has a wide range, and the response will contain eddy current energy from multiple frequency components.(2) Since the eddy current penetration depth is related to the frequency of the excitation source, all defect information within a certain depth can be obtained from one single pulse excitation. Higher input voltages are applied than in ECT because the energy is spread over a wide frequency band. Since the magnetic field created in the primary coil can penetrate through any nonmagnetic material, PECT can be performed without being in contact with the structural elements and without removing the protective coatings of structural elements. Figure 1 shows the detection of the wall thickness of a steel tube using a commercial PECT device after corrosion.

Figure 1. Photo. Using PECT to measure loss of wall thickness because of corrosion.(3)

Physical Principle

Similar to ECT, PECT is based on the principle of electromagnetic induction. Unlike ECT, which uses a single-frequency sinusoidal electrical signal, PECT employs a rectangular pulse excitation. Eddy current energy is coupled to the specimen by increasing and decreasing the amplitude of the excitation. The eddy current then generates a magnetic field that induces a voltage change in the receiving coil of the PECT system. When moved past a defect, the probe output will show a waveform with a peak amplitude decaying to zero. By comparing the voltage signal to a signal from an intact specimen, the defect and its depth can be detected. The pulse can be expanded into a large number of harmonic components using a Fourier transform algorithm. The maximum depth of anomaly detection is related to the frequency of excitation. The lower the frequency is, the deeper the eddy current can reach. The decay rate of the voltage after the peak amplitude is related to the depth of the defect. A lower decay rate corresponds to a larger depth of the defect.

Data Acquisition

Data acquisition with PECT should follow the manufacturer’s manual. Tests are usually simple and fast to perform with commercial PECT equipment. Each reading takes a few seconds. The PECT instrument takes point measurements. Contact with the specimen being tested and surface preparation are not needed. During a PECT test, the probe must be held stationary. The probe should only be moved when data collection is complete.

Data Processing

Data processing, which is performed by software incorporated into the PECT instrument, provides an instantaneous estimate of the wall thickness or defect location through comparison with a reference signal. For some applications (e.g., wall thickness measurement), these readings are sufficiently accurate, and no further analysis is required. More demanding applications (e.g., estimating the size or location of a defect) require more detailed analyses. Detailed analyses can be done after the inspection by connecting the instrument to a computer and downloading the stored data. The data can be further processed using proper software by an experienced inspector or engineer.

Data Interpretation

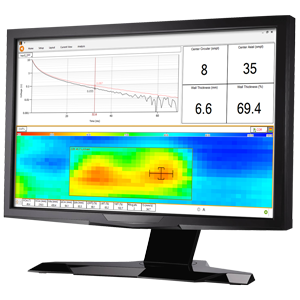

Results of PECT can be presented as a color-coded map, graph, or table to reflect the thickness or defect depth at different locations of the specimen. Figure 2 shows the minimum wall thickness of a steel specimen measured with PECT. A color-coded map (in which orange represents thin walls and indicates potential defects in the specimen, and blue represents normal wall thicknesses and indicates an intact area of the specimen) is shown in the lower part of the result screen. By moving the location of the cursor (black cross in figure 2) over the color-coded map, the detailed waveform and results at each test location are provided in the upper part of the result screen.

Figure 2. Image. Minimum wall thickness of a specimen measured with PECT.(3)

Advantages

Advantages of PECT include the following:

- Information from a range of depths can be obtained simultaneously.

- Contact with the surface of the material is not needed.

- No surface preparation or removal of protective coating is required.

- Readings at the same locations are reproducible.

Limitations

Limitations of PECT include the following:

- Application is limited to carbon steel and low-alloy steel.

- Isolated pitting defects are difficult to detect.

- Variations in the electromagnetic properties of the material will affect testing results.

- Geometry of the test object should be simple.

References

- Auld, B.A. and Moulder, J.C. (1999). “Review of advances in quantitative eddy current nondestructive evaluation.” Journal of Nondestructive Evaluation, 18(1), pp. 3–36, Springer, Basingstoke, England.

- Huang, S. and Wang, S. (2016). New Technologies in Electromagnetic Non-destructive Testing, Springer, Basingstoke, England.

- Eddyfi Technologies. “Lyft: Pulsed Eddy Current Reinvented.” (website) Quebec, Canada. Available online: https://www.eddyfi.com/lyft/, last accessed October 4, 2018.