Pavements - Nuclear Density Gauge (NDG)

Target of Investigation

The nuclear density gauge is a rapid, nondestructive device primarily used to measure the density of in‑place earthworks, granular and stabilized pavement materials, and hot mix asphalt (HMA) during construction and service life.(1–3) Specific applications include the following:

- Conducting quality control and, on some occasions, quality acceptance during construction.

- Establishing effective rolling effort and pattern to achieve proper density.

- Estimating the density and/or moisture content of an existing exposed material.

Description

Density is a critical property of compacted materials that can be related to the long-term performance of pavements. The most accurate method for determining the density of a pavement is to extract cores and test them in a laboratory, but this method is expensive and time consuming.(4) The nuclear density gauge (figure 1) is a portable, rapid, and virtually nondestructive alternative.(5)

© 2018 Pavement Interactive. https://www.pavementinteractive.org.

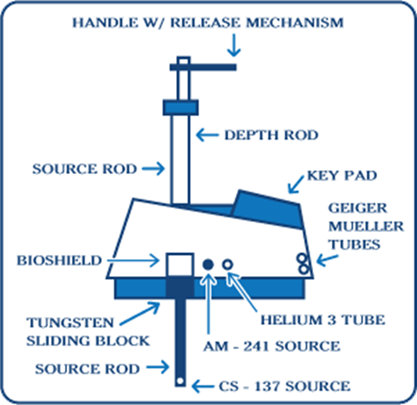

© 2018 Pavement Interactive. https://www.pavementinteractive.org.As shown in figure 2, the nuclear density gauge consists of a handle, a retractable rod, a frame, a Cesium-137 (Cs-137) source and Geiger–Mueller detector for density measurements, and an Americium-241 (Am-241) neutron source and Helium-3 (He-3) tube detector for moisture content measurements.(6)

© 2015 American Portable Nuclear Gauge Association.

© 2015 American Portable Nuclear Gauge Association.Because of the radioactive source material, the use and transport of this system is regulated by the United States Nuclear Regulatory Commission and State regulatory commissions and requires special certifications and permits.(1–3,7) Manufacturers are required to provide safety materials, and operators are required to complete training courses for safe use of the system.

Physical Principle

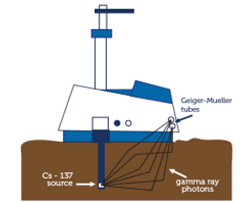

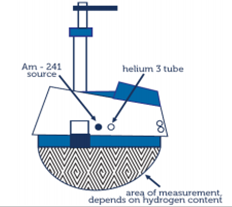

The nuclear density gauge measures the decay of Cs-137 by recording the count rate of the radiation transmitted directly through the pavement material from the Cs-137 source to the Geiger–Mueller tubes. These counts are then translated to the wet density of the material through a calibration process.(7) High-energy (fast) neutrons are emitted by an Am-241 radiation source and detected and counted by the He-3 tube. The fast neutrons are slowed by interactions with hydrogen atoms.(6) A wetter material will slow a greater number of neutrons; the gauge counts the rate of slow neutrons to measure the moisture content. The device is placed on the surface of the pavement, and the sources and appropriate detectors are activated to measure the number of gamma rays and neutrons.

Direct Transmission

In direct transmission mode (figure 3-A), the retractable rod is lowered from its protective sheathing into the pavement through a predrilled hole. The source emits gamma rays; those that maintain sufficient energy are counted by the detector. The denser the material is, the lower the detector’s count will be. This method is generally effective up to depths of 300 mm (12 inches).(6,7)

Backscatter

In backscatter mode (figure 3-B), the retractable rod is lowered from its protective sheathing but only until it is even with the detector. The source emits gamma rays; those that scatter back in the direction of the detector are counted. This method is generally effective up to depths of

75–100 mm (3–4 inches).(1–3)

© 2009 American Portable Nuclear Gauge Association.A. Direct transmission.

© 2009 American Portable Nuclear Gauge Association.A. Direct transmission. © 2009 American Portable Nuclear Gauge Association.B. Backscatter transmission.

© 2009 American Portable Nuclear Gauge Association.B. Backscatter transmission.Data Acquisition

Detailed procedures for the operation of specific nuclear density gauges are supplied by manufacturers, and procedures for using the devices are given in the following ASTM standards:

- ASTM D6938, Standard Test Methods for In-Place Density and Water Content of Soil and Soil Aggregate by Nuclear Methods (Shallow Depth).(1)

- ASTM D2950/D2950M, Standard Test Method for Density of Bituminous Concrete in Place by Nuclear Methods.(2)

- ASTM C1040/C1040M, Standard Test Methods for In-Place Density of Unhardened and Hardened Concrete, Including Roller Compacted Concrete, by Nuclear Methods.(3)

These ASTM standards provide extensive details on the use of the devices (including recommended distances to vertical surfaces and other devices, appropriate air gaps between the device and the surface, and other factors).

Before testing, calibration and standardization procedures should be performed to ensure accurate measurement with nuclear density gauges. A standardization check should be performed at the beginning of each work day and include taking reference measurements on a standard block to ensure the device’s gamma ray counts correlate to the correct densities. Figure 4 shows a gauge in use. Simplified procedures for direct transmission and backscatter modes follow.

© 2018 Pavement Interactive. https://www.pavementinteractive.org.

© 2018 Pavement Interactive. https://www.pavementinteractive.org.Direct Transmission

The following are steps for using the gauge in direct transmission mode:

- Select a test location of interest.

- Use the guide plate and a hole-forming device (usually a steel rod on unhardened surfaces and a drill on hardened surfaces) to make a perpendicular hole for the source rod probe.

- Insert the probe so that the side facing the gauge is in contact with the side of the hole (do not insert the probe until the device is sitting on the surface).

- Perform the warmup procedure as indicated in the manufacturer’s instructions.

- Take the in-place density reading following the manufacturer’s instructions.

- Retract the source rod probe.

Return the device to its protective case when not in use (i.e., between measurements).

Backscatter

The following are steps for using the gauge in backscatter mode:

- Select a proper test location.

- Seat the gauge firmly against the surface to ensure maximum contact between the device and the material.

- Perform the warmup procedure as indicated in the manufacturer’s instructions.

- Take the in-place density reading following the manufacturer’s instructions.

Return the device to its protective case when not in use (i.e., between measurements).

Data Processing

Nuclear density gauges directly report the density and moisture content (when appropriate) if the device is properly calibrated for the testing material. Accurate values are achieved only by applying the calibration procedures on known samples in the laboratory and a field check on a test strip.

The following factors may interfere with density measurements:(1–3)

- Density of the underlying material, especially when measuring HMA overlays (most significant in backscatter mode).

- Presence of reinforcing steel.

- Sample heterogeneity.

- Chemical composition of the test material.

- Spatial bias; the gauge is more sensitive to the material closest to the source.

- Surface roughness.

- Oversize aggregate particles in the source detector path.

Data Interpretation

Measurements provided by a nuclear density gauge can be used to determine the relative density and, if applicable, the moisture content during construction. In order to calculate the relative density, the maximum density should be determined in a laboratory and entered into the device before initiating the tests.

Advantages

Advantages of nuclear density gauges include the following:

- Is portable enough for one operator.

- Produces results in a matter of minutes.

- Is completely nondestructive in the backscatter mode.

- Provides simultaneous density and moisture content for granular materials.

Limitations

Limitations of nuclear density gauges include the following:

- Radioactive source material is a safety hazard.

- State and Federal permits are required for use and transport.

- Operator training is required.

References

- ASTM D6938. (2017). “Standard Test Methods for In-Place Density and Water Content of Soil and Soil Aggregate by Nuclear Methods (Shallow Depth).” Book of Standards 04.09, ASTM International, West Conshohocken, PA.

- ASTM D2950/D2950M. (2014).“Standard Test Method for Density of Bituminous Concrete in Place by Nuclear Methods.” Book of Standards 04.03, ASTM International, West Conshohocken, PA.

- ASTM C1040/C1040M. (2016). “Standard Test Methods for In-Place Density of Unhardened and Hardened Concrete, Including Roller Compacted Concrete, by Nuclear Methods.” Book of Standards 04.02, ASTM International, West Conshohocken, PA.

- Pavement Interactive. (2010). “Compaction Measurement and Reporting.” (website) Available online: https://www.pavementinteractive.org/reference-desk/construction/

compaction/compaction-measurement-and-reporting/, last accessed May 1, 2018. - Pavement Interactive. (2010). “Nuclear Density Gauge.” (website) Available online: https://www.pavementinteractive.org/reference-desk/construction/compaction/nuclear-density-gauge/, last accessed May 1, 2018.

- American Portable Nuclear Gauge Association. “Gauge Basics.” (website) Emmitsburg, MD. Available online: https://www.apnga.com/industry-info/gauge-basics/, last accessed May 1, 2018.

- Roads & Maritime Services. (2015). Field Density Testing By Using A Nuclear Density Gauge, Technical Guide L-G-002, NSW Government, Sydney, Australia. Available online: https://www.rms.nsw.gov.au/business-industry/partners-suppliers/documents/test-methods/field-density-testing-by-using-a-nuclear-gauge.pdf, last accessed May 1, 2018.

- American Portable Nuclear Gauge Association. (2009). APNGA Manual, Emmitsburg, MD. Available online: https://www.apnga.com/training-manual/, last accessed May 17, 2018.

- Pavement Interactive. (2012). “Nondestructive Pavement Evaluation Tools.” (website) Available online: https://www.pavementinteractive.org/nondestructive-pavement-evaluation-tools/, last accessed September 13, 2019.