Bridge - Moisture Content Measurement

Target of investigations

Estimating the moisture content of wood is important as the potential for wood decay increases for moisture contents greater than 20 percent, and serious decay can occur at moisture contents above 30 percent. High moisture levels can occur when wood is exposed to rain, groundwater, or moisture infiltration.(1) Fully saturated members do not develop fungi decay due to the lack of oxygen; however, since the water level of rivers or streams tend to change with time, timber piles are prone to fungal decay, especially at the water’s surface (i.e., the mud zone).(1)

Description

Rather than directly measuring the wood moisture level, electrical moisture meters estimate the moisture level of wood by measuring the change in its electrical properties such as conductivity (inverse of resistivity), dielectric constant, or power loss factor due to absorbing moisture.(2)

Physical Principle

The electrical properties of wood can change by approximately 10 orders of magnitude as its possible moisture content changes. Such a high sensitivity to the presence of moisture has led to the common application of electrical-based techniques for the accurate prediction of the wood moisture content.(2) The electrical-based techniques commonly estimate the conductivity of wood members using direct current (DC) and typically measure the dielectric properties of wood with an alternating current (AC).

Conductivity

The relationship between the applied DC voltage (V) and measured current (I) at the two ends of a conducting member with length L, and cross-section area A is as follows:

Where ρ is resistivity, and it has a unit of Ω.m. Furthermore, conductivity (σ) is equal to 1/ρ.(2)

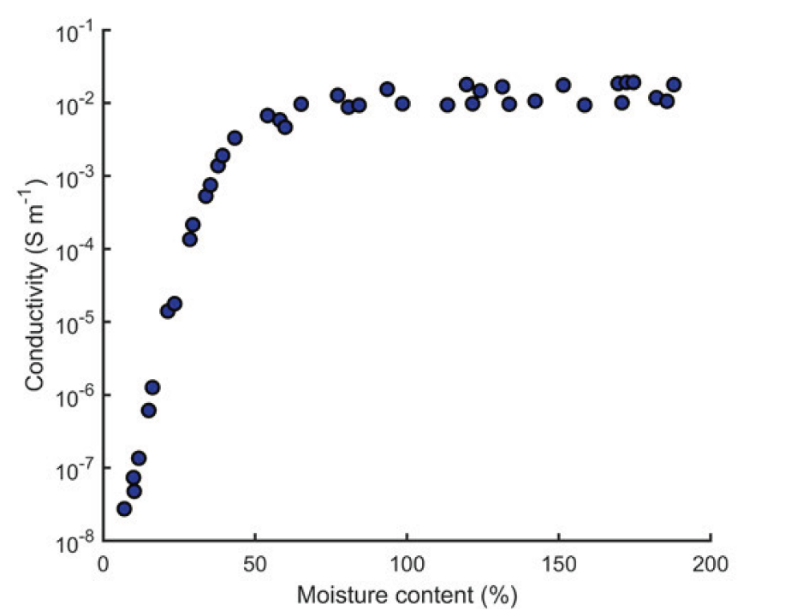

The conductivity of wood is substantially affected by its moisture content. The conductivity of oven-dried wood is in the order of 10-16-10-15 S m,-1, while at fiber saturation, it is in the order of 10-4-10-3 S m-1. From fiber saturation level to a fully saturated wood, conductivity typically increases less than one hundred times.(2) For example, the conductivity of slash pine in the longitudinal direction for moisture content between 8 percent and 180 percent is shown in figure 2.

Figure 2. Scatter plot. Conductivity versus moisture content of slash pine.(2)

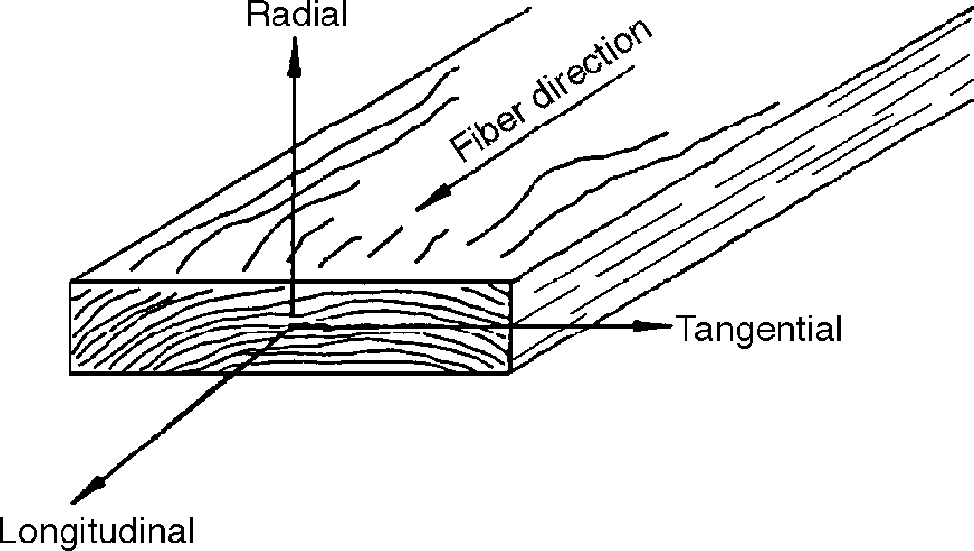

Wood conductivity is also influenced by the fiber direction and temperature.(2) Conductivity tends to increase with temperature. Furthermore, conductivity is higher along fibers (grains) than across them, with slightly higher in the radial direction than tangential direction (figure 3). The ratio of electrical conductivity in the longitudinal, radial, and tangential directions is approximately 1.0:0.55:0.5.(2)

Figure 3. Schematic. Principal axes of wood with respect to fiber direction and annual growth rings.(1)

Dielectric properties

When the alternating current is used, the dielectric constant of material can be expressed as follows:

Where , is the real part of the dielectric constant and ε” is the imaginary part. In the wood literature, it is common to refer to ε‘ as the dielectric constant.(2)

Both ε‘ and ε” are frequency- and temperature-dependent. At 1 MHz, the ε’ of dry wood is approximately 3, and that of wet wood is approximately 100. At each frequency, ε” increases with moisture content and temperature. ε’ is larger parallel to the grain than across the grain.(2)

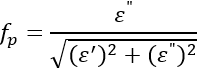

Another parameter is the power factor (fp), which can be expressed as follows:

fp is a measure of the heat produced as a dielectric material is exposed to an electric field, and it is used in dielectric moisture meters to estimate the moisture content of wood. The power factor of wood varies from 0.01 for dry and low-density wood to 0.95 for wet and dense wood. The power factor is usually larger along the grain than across the grain. Similar to , fp is affected by frequency, moisture, and temperature.(2)

Data Acquisition

There are two main types of electrical moisture meters: conductance type and dielectric-based moisture meters. The conductance type electrodes measure the conductivity of direct current between the device’s two electrodes. On the other hand, the dielectric-based moisture meters can measure either the dielectric constant or power loss factor. The ones that estimate the dielectric constant are referred to as capacitance or capacitive admittance meters, while the electrical moisture meters that measure the power loss factor are called power loss meters.(2)

The electrodes of conductance-type moisture meters (up to 3 inches long) can be driven into the timber to assess the electrical resistance between two pins (figure 6). These electrodes are either uninsulated or insulated, except for the tip of the electrodes. The uninsulated electrodes estimate the lowest resistance along their lengths, while insulated electrodes give the resistance at their tips. The 3 inch-long insulated electrodes (pin-style electrodes) are highly recommended for bridge applications and allow for determining moisture gradients along the penetration depth. Results from the conductance-type moisture meters need to be corrected for the temperature and type of species. Approximate correction for wood temperature involves adding 0.5 percent for each 10 ℉ temperature lower than the device’s calibration temperature and subtracting 0.5 percent for each 10 ℉ temperature higher than the device’s calibration temperature. Newer moisture meters include settings for automatic corrections based on the species and entered temperature.

Furthermore, the type of preservatives can affect results. Since the resistance of a medium is affected by the presence of salts, the use of conductance-type moisture meters in estimating the moisture content of timber pressure treated with salt-based preservatives (i.e., alkaline copper quaternary and chromated copper arsenate can be unreliable.(3) In this case, drill cores can be used to determine moisture content via oven-dry methods (ASTM 4442(4) or ASTM D4444(5)).

Figure 6. Photo. Conductance type (pin-style) moisture meter.(1)

The newer capacitance electrodes are mainly sensitive to the near-surface moisture of timber members, and they require specific gravity to estimate the moisture content.(2) The specific gravity can be provided by selecting the species type on the device. These moisture meters correct for the wood temperature internally. The reliable range of estimating moisture for the commercial conductance electrodes is 6 percent to 30 percent, and for capacitance moisture meters is 4 percent to 30 percent. Readings above 30 percent should be considered qualitative.(2)

Data Processing

Depending on the temperature during testing, conductivity measured by the conductance-type electrodes may need correction for the temperature effects.

Data Interpretation

The moisture content of wood does not provide direct information about the presence of decay, but it suggests the potential for decay. Moisture contents above 20 percent indicate the potential for decay with significant decay at moisture contents above 30 percent. The presence of salt in wood due to treatment with salt-based preservatives or longtime exposure to seawater can result in inaccurate moisture content measurements.

Advantages

Some of the advantages of moisture content measurement include the following:

- Simplicity.

- Low cost.

- Well-established field inspection technique.

- Quantitative information provided about the moisture content of wood members, which is a key biotic requirement for sustaining decay activity.

Limitations

Some limitations of moisture content measurement include the following:

- Moisture content measurement is not a direct measure of decay.

- Conductance-type meters may not be useful for wood treated with salt-based preservatives, exposure to seawater, and treated with fire retardants.

- Additional testing is needed to confirm the presence of decay.

References

- White, R. H., and R. J. Ross, eds. 2014. Wood and Timber Condition Assessment Manual. 2nd ed. General Technical Report No. FPL-GTR-234. Madison, WI: U.S. Department of Agriculture, Forest Service, Forest Products Laboratory.

- Forest Products Laboratory. 2021. Wood Handbook—Wood as an Engineering Material. General Technical Report No. FPL-GTR-282. Madison, WI: U.S. Department of Agriculture, Forest Service, Forest Products Laboratory.

- Brashaw, B. K., J. P. Wacker, and R. J. Ross. 2014. Advanced Timber Bridge Inspection Field Manual for Inspection of Minnesota Timber Bridges. Minneapolis, MN: University of Minnesota and Minnesota Department of Transportation.

- ASTM International. 2020. Standard Test Methods for Direct Moisture Content Measurement of Wood and Wood-Based Materials. ASTM D4442-20. West Conshohocken, PA: ASTM International. https://www.astm.org/d4442-20.html, last accessed February 7, 2022.

- ASTM International. 2018. Standard Test Method for Laboratory Standardization and Calibration of Hand-Held Moisture Meters. ASTM D4444-13R18. West Conshohocken, PA: ASTM International. https://www.astm.org/d4444-13r18.html, last accessed February 7, 2022.