Pavements - Microphones (MP)

Target of Investigation

Noise can be defined as unwanted or unpleasant sound. Road noise affects people in residences and businesses as well as people in vehicles. Microphones can be used to measure road-surface, engine, and aerodynamic noise.

Description

Noise generated by passing vehicles comes from three sources: air passing over and around the vehicle; the operation of the engine, exhaust, and drivetrain systems; and tire–pavement interactions.(1,2)

Tire–pavement noise can be measured by two test methods: the close proximity (CPX) method and the onboard sound intensity (OBSI) method.(3) The CPX method uses directional microphones inside an acoustically insulated, enclosed space built on a trailer towed behind a vehicle (figure 1). OBSI measurement uses directional microphones placed at the leading and trailing edges of the tire–pavement contact patch, just above the pavement (figure 2).

© 2009 AASHTO..A CPX test trailer.

© 2009 AASHTO..A CPX test trailer. © 2009 AASHTO.B. Closeup view of microphones.

© 2009 AASHTO.B. Closeup view of microphones. © 2009 AASHTO.

© 2009 AASHTO.The statistical pass-by (SPB) method measures noise from the roadside with microphones (figure 3). This method measures combined noise from vehicle engines, exhausts, and other sources.

© 2018 Acoustic Engineering Dresden.

© 2018 Acoustic Engineering Dresden.Physical Principle

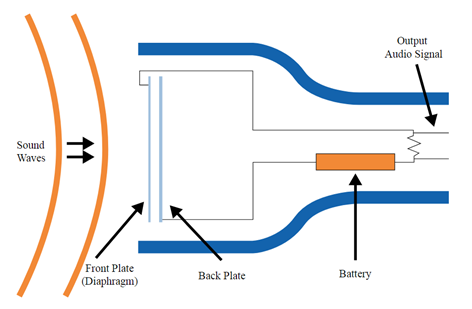

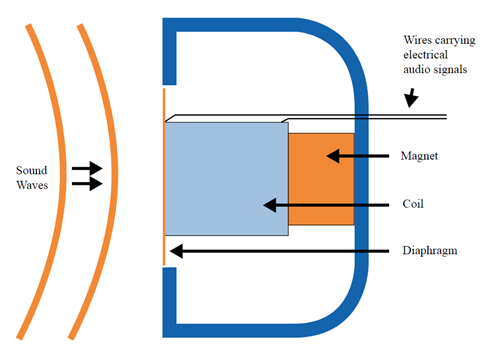

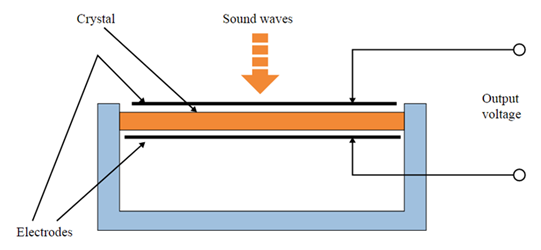

A microphone, which measures air pressure changes as sound waves pass by, is a transducer that detects sound (acoustic signal) and transforms it to a voltage or current that is proportional to the sound signal. Based on the way a microphone transforms an acoustic signal to an electrical signal, a microphone can be either a condenser, dynamic, or piezoelectric microphone.

A condenser microphone uses a capacitor to transform an acoustic signal into an electrical signal (figure 4). The sound pressure changes the spacing between a thin metallic membrane and the stationary back plate. The membrane and plate act as a capacitor when connected to a battery and resistor. A change in the plate spacing because of sound pressure causes a change in the capacitance, which forces a current through the resistor.

© 2018 DEWESoft®.

© 2018 DEWESoft®.A dynamic microphone takes advantage of electromagnetic effects (figure 5). A diaphragm is connected to either a magnet or a coil. When the sound waves excite the diaphragm, the relative movement between the magnet and coil induces an electrical current in the wire.

© 2018 DEWESoft®.

© 2018 DEWESoft®.A piezoelectric microphone features a sensitive crystal that respond to the physical vibration of acoustic signals by creating an electrical output (figure 6).

© 2018 DEWESoft®.

© 2018 DEWESoft®.Data Acquisition

The procedures for measuring tire–pavement noise using the CPX method can be found in ISO 11819-2, Acoustics – Measurement of the influence of road surfaces on traffic noise – Part 2: The close-proximity method.(7) The procedures for measuring tire–pavement noise using the OBSI method can be found in AASHTO TP 76, Standard method of test for measurement of tire/pavement noise using the on-board sound intensity (OBSI) method.(8) The procedures for measuring the influence of road surfaces on highway traffic noise at a specific site by using the SPB method can be found in ISO 11819-1, Acoustics ‒ Measurement of the influence of road surfaces on traffic noise ‒ Part 1: Statistical Pass-By method.(9)

A signal acquisition system can be used to collect and store the data. For OBSI and CPX tests, data are collected continuously as the vehicle moves on the road surface. For SPB tests, data are collected for a time period for a certain group of vehicles travelling at a certain speed.

Data Processing

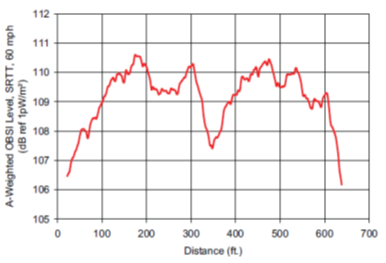

For CPX and OBSI methods, noise is time-sequence data and can be processed to identify the noise level at different areas of a pavement. For an individual test section, a single overall sound‑intensity level is often cited. This value is usually expressed in A-weighted decibels (dBA), representing an average over the length of the test section. A-weighting represents an approximation of sound or noise perceived by the human ear. The sound-intensity spectrum provides the frequency content to inspect tire–pavement noise.

For the SPB method, data are correlated to vehicle types and speeds by statistical analyses.(10) For each vehicle category, the maximum pass-by noise levels are regressed against the logarithm of vehicle speed. The SPB level for each vehicle category is defined as the ordinate of the regression line at the reference speed for the road category. The sound-intensity spectrum may also be reported for different vehicle categories at the reference speed.

Data Interpretation

A larger test result usually indicates a higher noise level of the pavement. CPX and OBSI levels can be calculated using short interval averages and plotted as a function of distance along the road (figure 7). SPB results for each segment of road can be shown in a tabular form for different categories of vehicles at the reference speed.

© 2011 The Transtec Group, Inc.1 ft = 0.3 m.

© 2011 The Transtec Group, Inc.1 ft = 0.3 m.Advantages

Advantages of using microphones to measure noise include the following:

- The SPB method can eliminate the variability of noise emissions from different vehicles within each type.(5)

- The SPB method measures near the receptors along a roadway and is more representative of actual traffic conditions.(5)

- CPX and OBSI methods measure at arbitrary locations and continuously along sections of road.(5)

Limitations

Limitations of using microphones to measure noise include the following:

- For the SPB method, the road section to be tested must be flat, straight, and at an open location with no large reflective objects in the immediate vicinity.(5)

- Because SPB test measurements are taken at a specific location, the results can only be related to short test sections of road surface. Heterogeneous surface texture cannot be evaluated.(5)

- CPX and OBSI methods do not take into consideration noise sources other than

tire–pavement interaction noise.

References

- Nelson, P.M. and Phillips, S.M. (1997). “Quieter Road Surfaces.” TRL Annual Review, Transportation Research Laboratories, Berkshire, UK.

- Sandberg, U. (2001). “Tyre/Road Noise Myths and Realities.” INTER-NOISE and NOISE‑CON Congress and Conference Proceedings, Hague, Netherlands.

- Federal Highway Administration. (2017). “Tire-Pavement Noise.” (website) Washington, DC. Available online: https://www.fhwa.dot.gov/pavement/sustainability/articles/tire_noise.cfm, last accessed March 12, 2019.

- Donavan, P.R. and Lodico, D.M. (2009). Measuring Tire-Pavement Noise at the Source, Transportation Research Board, Washington, DC.

- Acoustic Engineering Dresden. (2018). “SPB – Statistisches Vorbeifahrt-Verfahren.” (website) Dresden, Germany. Available online: https://www.akustikforschung.de/en/leistungen/umweltakustik/strassenlarm/spb-statistisches-vorbeifahrt-verfahren/, last accessed May 10, 2018.

- DEWESoft. “Sound pressure measurement.” (website) Trbovlje, Slovenia. Available online: https://training.dewesoft.com/online/course/sound-pressure-measurement, last accessed December 5, 2019.

- ISO 11819-2. (2017). Acoustics ‒ Measurement of the influence of road surfaces on traffic noise ‒ Part 2: The close-proximity method, International Organization for Standardization, Geneva, Switzerland.

- AASHTO TP 76. (2013). Standard method of test for measurement of tire/pavement noise using the on-board sound intensity (OBSI) method, American Association of State Highway and Transportation Officials, Washington, DC.

- ISO 11819-1. (1997). Acoustics ‒ Measurement of the influence of road surfaces on traffic noise ‒ Part 1: Statistical Pass-By method, International Organization for Standardization, Geneva, Switzerland.

- Dick, E.B., Izevbekhai, B.I., and Casey, T. (2010). Influence of Pavement on Traffic Noise – Statistical Pass-By Measurements of Traffic on Several Interstate Pavements, Report No. MN/RC 2010-40, Minnesota Department of Transportation, St. Paul, MN.

- Rasmussen, R.O., Sohaney, R., and Wiegand, P. (2011). Measuring and Reporting Tire‑Pavement Noise Using On-Board Sound Intensity (OBSI), National Concrete Pavement Technology Center, Ames, IA.