Tunnel - Magnetic Particle Testing (MT)

Target of Investigation

Magnetic particle testing (MT) can be applied to steel members in tunnels if the surface of the member is accessible. MT is commonly used to detect surface cracks in steel girders, steel truss members, and ancillary steel structures, such as sign supports and light poles. The method can be applied to inspect the quality of welds during the fabrication process or to detect cracks that develop in structures from service loads.

Description

MT is a method of locating surface and subsurface discontinuities in ferromagnetic materials. When a part being tested is magnetized, surface cracks cause magnetic field deviations to form above the part’s surface; this is known as magnetic field leakage. Finely divided ferromagnetic particles are applied over the surface of the part. Either dry or wet magnetic particles (delivered in a liquid carrier, such as water or oil) can be used. Some of the particles are gathered and held by the leakage field; this indicates the presence of a discontinuity. This magnetically held collection of particles forms an outline of the discontinuity and indicates its location, size, shape, and extent.

Physical Principle

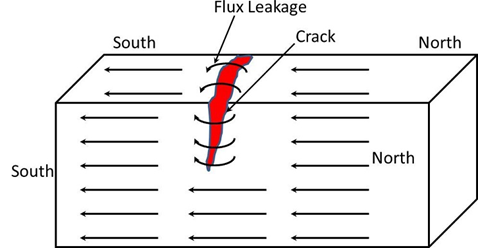

MT works on the physical principles of magnetic induction and magnetic field leakage. This method can only be applied to ferromagnetic materials, such as steel. When a specimen is subjected to a magnetic field, the presence of a defect will cause local distortions in the magnetic field around the defect area. This effect is referred to as magnetic-flux leakage. If fine particles of magnetic material are placed on the specimen in the presence of the magnetic field, they will align with the magnetic-flux lines and the disruption of those lines caused by a defect. This phenomenon is illustrated in figure 1.

Figure 1. Illustration. Basic principle of a magnetic particle.

Data Acquisition

MT is typically applied using a “dry powder” method for crack detection in steel structural components. Magnetic particles infused with a colored dye are broadcast onto the surface of the material being tested. A blower may be used to remove excess powder from the surface. Particles not confined by a magnetic field are removed, and particles confined by magnetic forces remain, forming the indication.

Surface preparation for applying MT includes removing coatings to ensure effective coupling of the magnetic field into the material being tested. Removing the coating also reduces the likelihood of nonrelevant indications forming from debris on the surface or imperfections in the coating itself. Debris or imperfections in the coating can mechanically confine the particles, resulting in a nonrelevant indication. Care must be taken to ensure crack openings are not obscured during mechanical coating removal processes (e.g., grinding).

The orientation of the magnetic fields induced in the material must be orthogonal to a crack opening to ensure a sufficient leakage field to capture magnetic particles. Direct magnetization using prods develops circular magnetic fields around each prod. Consequently, the crack must lie parallel to an imaginary line connecting the prods. In contrast, indirect magnetization results in a magnetic field in the material that is parallel to an imaginary line connecting magnet yokes. Therefore, the crack must be orthogonal to an imaginary line connecting the yokes. When the orientation of cracks is not known, procedures for MT typically require reorientation of the yokes or prods in orthogonal positions to ensure cracks are detected reliably.(1)

Data Processing

Crack indications are detected by visual inspection. Therefore, no data processing is required.

Data Interpretation

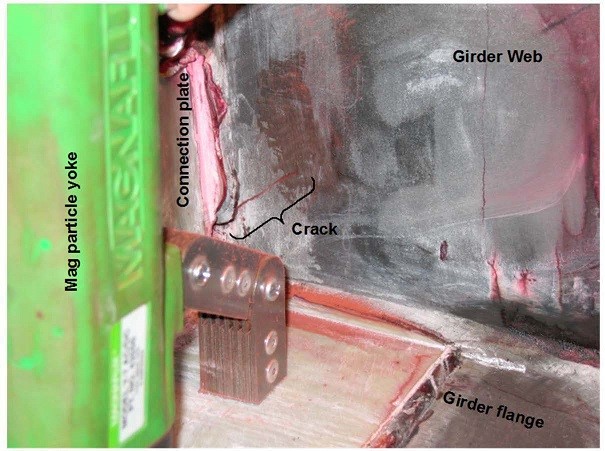

The primary data acquired from MT are indications on the surface of the material created from accumulated magnetic particles. These indications are interpreted by an inspector to determine if the source of the indication is a crack or if the indication is caused by a noncrack geometric feature, contamination on the surface of the material, or some other nonrelevant source. Relevant indications (i.e., crack indications) are documented by the inspector through notes, photographs, and/or diagrams. Figure 2 shows typical MT crack indications in a weld that connects a vertical stiffener to a girder web.

Figure 2. Photo. Crack exposed using MT.

Advantages

Advantages of MT include the following:

- Low cost.

- Widely available on a commercial basis.

- Minimal data processing.

- Simple interpretation of results.

Limitations

Limitations of MT include the following:

- Only surface-breaking or very-near-surface flaws are detectable.

- Surface preparation is required.

References

- ASTM E709-15. (2015). “Standard Guide for Magnetic Particle Testing.” Book