Pavements - Locked-Wheel Tester (LWT)

Target of Investigation

The locked-wheel test is used to measure the skid resistance of pavement.

Description

Skid resistance is an important pavement evaluation parameter. Adequate skid resistance is needed to reduce the risk of skid-related crashes.

In the United States, a locked-wheel tester (figure 1) is the most common method of measuring skid resistance. A typical measurement system for a locked-wheel skid includes a test vehicle with one or more test wheels incorporated into it or as part of a towed trailer. Ribbed or smooth tires can be used.(1) A ribbed tire is more sensitive to microtexture changes in the pavement, while a smooth tire is more sensitive to pavement macrotexture. American Association of State Highway and Transportation Officials (AASHTO) M 261 and ASTM E501 define the standard ribbed tire for the test; ASTM E524 defines the standard smooth tire.(2–4) The vehicle (or trailer) is brought to the desired testing speed, and water is sprayed ahead of the test tire to create a wet pavement surface. The test tire’s braking system is actuated to lock the test tire. Instrumentation within the locked-wheel tester measures the friction force acting between the test tire and pavement and reports the result as a skid number.

© 2009 AASHTO.

© 2009 AASHTO.Physical Principle

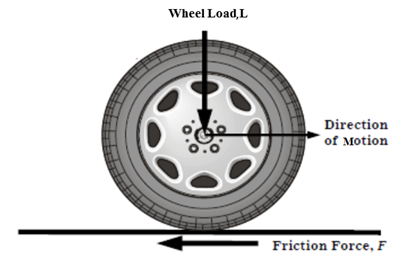

The locked-wheel test measures the skid resistance as a friction coefficient or skid number. As shown in figure 2, L is the load perpendicular to the interface. Once the test wheel is locked, a friction force (F) takes place on the interface of the locked wheel and the road surface.

© 2009 AASHTO.

© 2009 AASHTO.

Where f is the friction coefficient.

Where SN is the skid number.

Data Acquisition

A standard locked-wheel test can be performed according to AASHTO T 242, Standard Method of Test for Frictional Properties of Paved Surfaces Using a Full-Scale Tire, or ASTM E274, Standard Test Method for Skid Resistance of Paved Surfaces Using a Full-Scale Tire.(5,6)

According to ASTM E274, approximately 0.5s after the beginning of the water delivery, the test wheel’s brake should be applied to lock the wheel completely.(6) The wheel should remain locked for the duration of the data-averaging interval, which starts not less than 0.2s after the start of the wheel lockup. The interval should not be less than 1.0 or more than 3.0s. The data in the interval are averaged, and the mean value is used to estimate the skid number. Water delivery may be terminated as soon as the brake is released.

Data Processing

The friction coefficient and skid number are calculated with the equations in figure 3 and figure 4.

Data Interpretation

Data are usually presented in a tabular format. Agencies generally establish thresholds for the friction coefficient and skid number. If the test results are below these thresholds, the agency will investigate potential friction concerns.

Advantages

Advantages of locked-wheel testers include the following:

- Systems are user friendly and relatively simple.

- Testing is not time consuming.

- Testers operate at near highway speeds.

- Lane closures are usually not necessary.

Limitations

Limitations of locked-wheel testers include the following:

- The test can only be used on straight segments (no curves, T-sections, or roundabouts).(1)

- The test is a sample-based testing procedure. At 40 mi/h (65 km/h), the test reports the average skid resistance of approximately 60 ft (18 m) of road. Friction characteristics vary along the road surface; thus, the test may not be conducted in the location of interest.

- The skid resistance is only valid for the test speed. The relationships between skid resistance and speed need to be determined by repeated measurements under different speeds for the same sections of the road.(7)

- The test only measures skid resistance at a 100-percent slip ratio.

References

- National Academies of Sciences, Engineering, and Medicine. (2009). Guide for Pavement Friction, The National Academies Press, Washington, DC. Available online: https://doi.org/10.17226/23038, last accessed March 3, 2019.

- American Association of State Highway and Transportation Officials. (1996). Standard Specification for Rib-tread Standard Tire for Special-Purpose Pavement Frictional-Property Tests, AASHTO M 261, American Association of State Highway and Transportation Officials, Washington, DC.

- ASTM E501-08. (2015). “Standard Specification for Standard Rib Tire for Pavement Skid-Resistance Tests.” Book of Standards 04.03, ASTM International, West Conshohocken, PA.

- ASTM E524-08. (2015). “Standard Specification for Standard Smooth Tire for Pavement Skid-Resistance Tests.” Book of Standards 04.03, ASTM International, West Conshohocken, PA.

- American Association of State Highway and Transportation Officials. (1996). Standard Method of Test for Frictional Properties of Paved Surfaces Using a Full-Scale Tire, AASHTO T 242, American Association of State Highway and Transportation Officials, Washington, DC.

- ASTM E274. (2015). “Standard Test Method for Skid Resistance of Paved Surfaces Using a Full-Scale Tire.” Book of Standards 04.03, ASTM International, West Conshohocken, PA.

- Saito, K., Horiguchi, T., Kasahara, A., Abe, H., Henry, J. (1996). “Development of Portable Tester for Measuring Skid Resistance and Its Speed Dependency on Pavement Surfaces.” Transportation Research Record, 1536, pp. 45–51, Transportation Research Board, Washington, DC.