Pavements - Inertial Profiler – Pavement (IP)

Target of Investigation

Inertial profilers are primarily used to measure the profile of the pavement surface. Road profiles are analyzed to calculate a smoothness or ride quality index, the most common of which is the International Roughness Index (IRI).

Description

Smoothness is related to the ride quality of a pavement structure. Roughness is defined as a surface’s deviations from a true plane, with characteristic dimensions that affect a vehicle’s ride quality.(1) Rough or uneven pavement adversely affects driver safety, fuel efficiency, ride quality, vehicle and tire condition, and pavement durability.(1)

To quantify the smoothness of the road surface, inertial profiler data are used to develop road profiles. There are two types of inertial profilers available: high speed and lightweight.(2)

High-Speed Inertial Profilers

Transportation agencies use high speed inertial profilers (figure 1) for measuring pavement roughness. The measurement equipment is mounted on the front or rear of a data collection vehicle, and relevant data are collected at posted speeds. An inertial profiler may be equipped with additional components that may be used to perform sign and signal inventories, take right-of-way video, produce two- and three-dimensional images of the pavement surface, and measure features like highway grade and cross slope.

Image courtesy of Rutgers Center for Advanced Infrastructure and Transportation/© 2016 Nenad Gucunski.

Image courtesy of Rutgers Center for Advanced Infrastructure and Transportation/© 2016 Nenad Gucunski.Lightweight Inertial Profilers

Lightweight inertial profilers (figure 2) employ the same technologies used in the high speed systems but on smaller, lightweight vehicles; this makes them ideal for testing newly constructed concrete pavements that do not yet have sufficient strength to support regular traffic loads. Most agencies that have inertial profiler-based smoothness specifications allow the use of lightweight profilers.

Rutgers CAIT/© 2016 N. Gucunski.

Rutgers CAIT/© 2016 N. Gucunski.Physical Principle

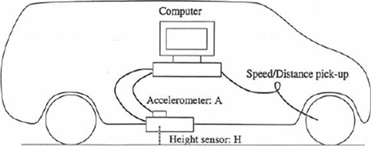

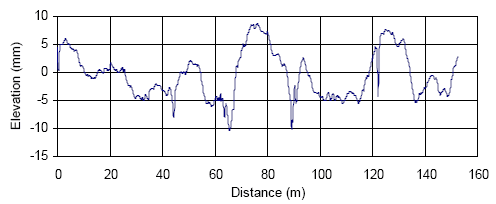

Figure 3 is a schematic diagram of a high speed inertial profiler. The inertial profiler system usually includes an accelerometer to measure the movement of the vehicle frame, noncontact sensors (commonly lasers) to measure the relative displacement between the vehicle frame and the road surface, and a distance-measuring instrument (DMI) to record the distance along the roadway. The data these sensors gather are collectively analyzed to produce a simulation of the longitudinal profile of the roadway via the equation in figure 4.

© 2005 The Regent of the University of Michigan.

© 2005 The Regent of the University of Michigan.

- Where:

- Profile elevation = simulated longitudinal profile.

- A = acceleration.

- H = height.

Data Acquisition

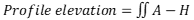

Figure 5 is a graphic profile recorded by a profiler. The profiler’s computer acquired the acceleration data from the accelerometer, the distance between the road surface and the base from the laser sensor and the distance traveled from the DMI. An algorithm calculated and recorded the profile of the pavement at each data location.

Source: FHWA.1 mm = 0.0393 inches; 1 m = 3.28 ft.

Source: FHWA.1 mm = 0.0393 inches; 1 m = 3.28 ft.Data Processing

Profile data can be used to calculate the IRI and ride number (RN) for a surface. Data that an inertial profiler records usually needs filtering to remove noise before further analysis.(4)

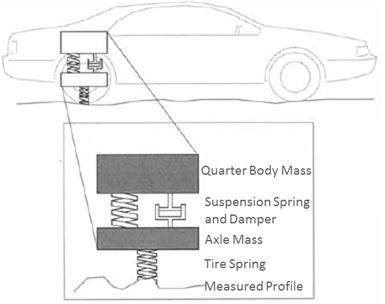

The computation of IRI is based on a mathematical model called a quarter-car model (figure 6). The response of the quarter car is simulated on the measured profile to calculate the suspension deflection. This simulation is performed for a speed of 50 mph (80.5 kph). The absolute values of the suspension’s movement, obtained from the simulation, are summed and then divided by the simulation length to obtain the average suspension movement over the simulated length. The IRI has units of slope; the most common units are inches per mile or meters per kilometer.

© 1998 The Regent of the University of Michigan.

© 1998 The Regent of the University of Michigan.The RN was developed to estimate the results of a 0 to 5 rating given by road users regarding a section of roadway. A RN of 0 represents the maximum possible roughness and a RN of 5 represents a perfectly smooth road.

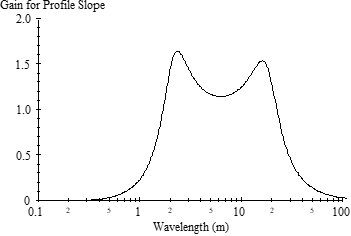

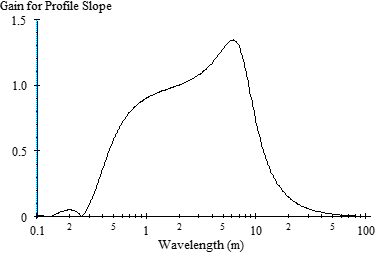

The gain plot provides an indication of the impact varying wavelengths in the longitudinal profile on the resulting IRI where gain represents an amplification (i.e., multiplier) on the wavelength. The wavelengths represent an approximate length of the event within the profile such that the longest wavelengths represent the grades of the roadway and the smallest wavelengths represent microtexture of the surface. Figure 7 provides the gain plot associated with the IRI which is most impacted by wavelengths of approximately 8 ft (2.4 m) and 50 ft (15.4 m).(6) The RN, as shown in Figure 8, is most sensitive to wavelengths of approximately 20 ft (6.1 m).(6)

Data Interpretation

The IRI and RN are usually presented in a tabular format. Acceptable IRI values depend on the class of road. For new asphalt highway pavements, they range from 52 to 66 inches/mile (0.810 to 1.030 m/km). For new concrete highway pavements, the range is from 57 to 72 inches/miles (0.890 to 1.130 m/km).(7)

Advantages

The following are advantages of using inertial profilers:

- Repeatability and accuracy are high.

- High speed inertial profilers can perform data collection at highway speeds.

- Data collection with high speed inertial profilers does not require lane closure.

- Lightweight inertial profilers can be used for testing before concrete has gained sufficient strength for regular traffic operations.

- Lightweight inertial profilers require a short lead-in distance to achieve testing speed and can be used in constrained construction zones.

Limitations

The following is a limitation of using inertial profilers:

- Inability to collect accurate data at low speeds (less than 15 to 20 mph) and stop-and-go conditions.(8)

- Data may be impacted by weather conditions such as falling precipitation or high wind with potential blown objects.

References

- California Department of Transportation (2021). “Pavement Profile Smoothness.” (website) Sacramento. CA. Available online: https://dot.ca.gov/programs/maintenance/pavement/concrete-pavement-and-pavement-foundations/smoother-pavements, last accessed July 19, 2021.

- Smith, K. and Ram, P. (2016). Measuring and Specifying Pavement Smoothness¸Report No. FHWA-HIF-16-032, Federal Highway Administration, Washington, DC. Available online: https://www.fhwa.dot.gov/pavement/pubs/hif16032.pdf, last accessed October7, 2019.

- Perera, R.W., Kohn, S.D., and Tayabji, S. (2005). Achieving a High Level of Smoothness in Concrete Pavements Without Sacrificing Long-Term Performance¸Report No. FHWA-HRT-05-068, Federal Highway Administration, Washington, DC.

- Perera, R.W. and Kohn, S.D. (2005). Quantification of Smoothness Index Differences Related to Long-Term Pavement Performance Equipment Type, Report No. FHWA-HRT-05-054, Federal Highway Administration, Washington, DC.

- Sayers, M.W. and Karamihas, S.M. (1998). The Little Book of Profiling: Basic Information about Measuring and Interpreting Road Profiles, University of Michigan Transportation Research Institute, Ann Arbor, MI.

- Karamihas, S.M., Gillespie, T.D., Kohn, S.D., and Perera, R.W. (1999). Guidelines for Longitudinal Pavement Profile Measurement, University of Michigan Transportation Research Center, Ann Arbor, MI.

- Merritt, D.K., Chang, G.K., and Rutledge, J.L. (2015). Best Practices for Achieving and Measuring Pavement Smoothness, A Synthesis of State-of-Practice, Louisiana Transportation Research Center, Baton Rouge, LA.

- Karamihas, S.M., Gilbert, M.E., Barnes, M.A., and Perera, R.W. (2019) Measuring, Characterizing, and Reporting Pavement Roughness of Low-Speed and Urban Roads, NCHRP Report 914, National Cooperative Highway Research Program, Washington, D.C.