Tunnel - Impact Echo (IE)

Target of Investigation

Primary applications of impact echo (IE) technology include the following:

- Detecting and characterizing defects, such as delamination and debonding in tnnel concrete lining and other members.(1)

- Measuring the thickness of slabs and walls.

Impact-echo has been successfully used as a means of non-destructive and time-effective evaluation of grouting quality in tunnel lining. (9)

Description

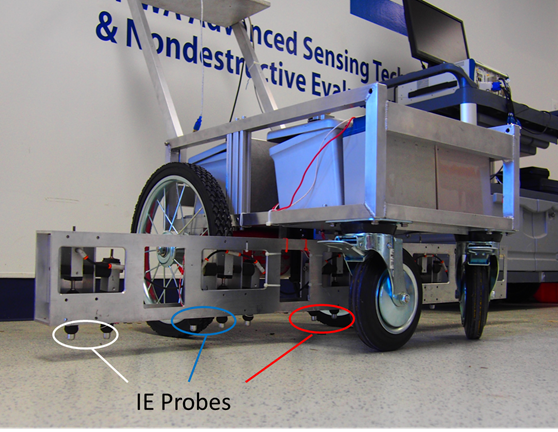

IE testing is a seismic or stress wave–based technology used to detect defects (primarily delamination) in concrete. The objective of an IE survey is to detect and characterize wave reflectors, or resonators, in a concrete structural element. IE devices can have multiple probes (figure 1) or a single probe (figure 2). Each probe consists of an impactor and receiver.

Figure 1. Photo. Acoustic array with multiple IE probe pairs.

Figure 2. Photo. Manual IE testing using a single probe and a closeup of the probe.(2)

Physical Principle

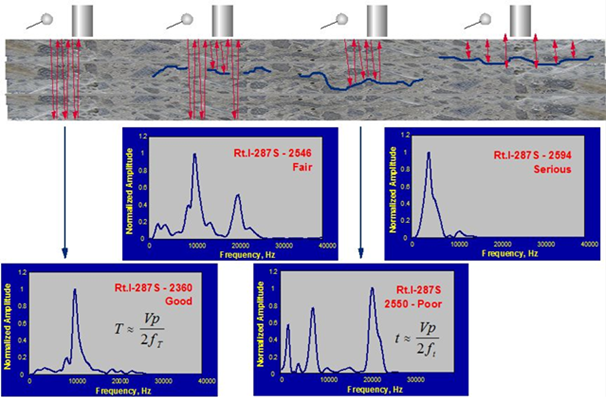

IE testing is conducted using an impactor and sensor. The impact generates waves that propagate within the solid material. Waves are reflected by internal defects (differences in acoustic impedance) or boundaries. The reflected waves, or echoes, return to the surface and are measured by the receiver. The multiple reflected waves monitored by the sensor manifest as resonance conditions in frequency domain analyses. Defects, such as delaminations and big voids, can be detected by changes in the resonant frequency compared to intact areas. The principle of IE testing is illustrated in figure 3. The resonant frequency of areas with deep delaminations is higher than that of the sound areas (thickness mode). The resonant frequency of areas with large shallow delaminations is lower than that of the sound areas owing to excitation of the flexural mode.

T = concrete slab thickness; Vp = pressure wave velocity; fT = resonance frequency of the thickness mode;

ft = resonance frequency of the delamination.

Figure 3. Illustration. Physical principle of IE.(3)

Data Acquisition

A complete data collection procedure is provided in ASTM C1383-15, Standard Test Method for Measuring the P-Wave Speed and the Thickness of Concrete Plates Using the Impact-Echo Method.(4)

The structural surface to be surveyed should be cleaned of debris before IE testing. The survey should be conducted on the densest grid possible. The grid should be marked using washable paint or chalk.

The impactor of the IE system should be carefully selected to provide enough energy in the frequency range of interest. Some impactors are equipped with a sensor to measure the characteristics of the impact. Many IE systems use steel balls of different sizes as impact sources; the center and maximum frequencies are inversely proportional to the diameters of the balls.

Data Processing

The amplitude spectrum obtained from the fast Fourier transform analysis of the time-domain signal will show dominant peaks at certain frequencies, which can be interpreted to assess the slab thickness or potential delamination or debonding.

The thickness mode normally dominates the spectral response of a platelike structure that does not contain any near-surface defects.(5) The frequency of the fundamental thickness mode can be related to the thickness of the member (figure 4).

- Where:

- T = thickness or depth of a defect.

- β = Correction factor.

- Cp = Compressive-wave velocity of concrete.

- fIE = IE frequency.

Accuracy or uncertainty in thickness estimates from IE testing depends on a pooled error of the return-frequency measurement and P-wave velocity determination (figure 4). The typical uncertainty in thickness measurement is 5–10 percent. (See references 3, 4, 6, and 7.) Other factors that may impact uncertainty include the stiffness of the underlying layer, closeness to boundaries, and texture of the concrete surface.(4)

Data Interpretation

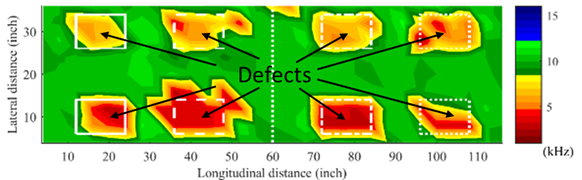

IE results are presented in various forms, some describing the position of reflectors, some interpreting the condition with respect to the state of delamination.(2) Figure 5 presents the dominant reflectors, or resonators, in terms of the spectral surface. The colors indicate different dominant frequencies identified in the response spectrum. Greens indicate normal thickness and no defects. Reds correspond to flexural oscillations of shallow delaminations.

1 inch = 2.54 cm.

Figure 5. Contour map. IE data presented as frequency.

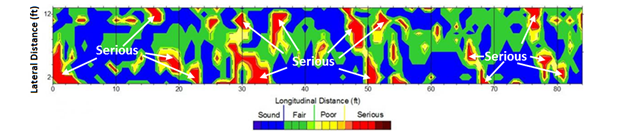

Results of IE tests often use different condition grades to indicate the progression of delamination development (figure 6). For example, fair and poor grades refer to incipient or progressed delamination, and serious grades correspond to either shallow or wide delamination.

1 ft = 0.305 m.

Figure 6. Contour map. Condition assessment with respect to delamination progression.(8)

Advantages

Advantages of IE testing include the following:

- Early detection of delamination.

- Capable of detecting debonding between layers, such as concrete-type overlays.

- Fast data analysis with respect to delamination characterization.

- Unambiguous data interpretation.

- Insensitive to traffic-induced vibrations.

- Reliable and repeatable when conducted properly by an experienced operator.

Limitations

Limitations of IE testing include the following:

- Moderate to significant expertise and training required for equipment setup and data collection, processing, and interpretation.

- Slow data collection using traditional single-probe equipment; requires traffic control and lane closure.

- Dense test grid necessary to accurately define the boundaries of delaminated areas, adding to the test duration.

- Complex evaluation of conditions for overlaid roadways; cannot assess the condition of slabs in areas where the overlay is debonded.

- Consideration of geometrical and boundary effects needed, especially for structural elements, such as girders, columns, and caps.

References

- Wimsatt, A., White, J., Leung, C., Scullion, T., Hurlebaus, S., Zollinger, D., Grasley, Z., et al. (2014). Mapping Voids, Debonding, Delaminations, Moisture, and Other Defects Behind or Within Tunnel Linings, Report No. S2-R06G-RR-1, Transportation Research Board, Washington, DC.

- Federal Highway Administration. (2003). Nondestructive Thickness of Distressed Concrete Pavement Using Impact-Echo, FHWA MCL Project No. 0207, FHWA, Washington, DC. Available online: https://www.fhwa.dot.gov/pavement/concrete/mcl0207.pdf, last accessed, December 3, 2019.

- Gucunski, N., Imani, A., Romero, F., Nazarian, S., Yuan, D., Wiggenhauser, H., Shokouhi, P., Taffee, A., and Kutrubes, D. (2013). Nondestructive Testing to Identify Concrete Bridge Deck Deterioration, Report No. S2-R06A-RR-1, Transportation Research Board, Washington, DC.

- ASTM C1383-15. (2015). “Standard Test Method for Measuring the P-Wave Speed and the Thickness of Concrete Plates Using the Impact-Echo Method.” Book of Standards 04.02, ASTM International, West Conshohocken, PA.

- Sansalone, M. and Carino, N. (1989). “Detecting Delaminations in Concrete Slabs with and without Overlays Using the Impact-Echo Method.” ACI Materials Journal, 86(2),

pp. 175–184, American Concrete Institute, Farmington Hills, MI. - Maser, K.R., Holland, T.J., Roberts, R., Popovics, J., and Heinz, A. (2003). Technology for Quality Assurance of New Pavement Thickness. Presented at the 82nd Annual Meeting of the Transportation Research Board, Washington, DC.

- Azari, H., Yuan, D., Nazarian, S., and Gucunski, N. (2012). “Sonic Methods to Detect Delamination in Concrete Bridge Decks: Impact of Testing Configuration and Data Analysis Approach.” Transportation Research Record, 2292, pp. 113–124, Transportation Research Board, Washington, DC.

- Strategic Highway Research Program, “SHRP2 NDToolbox,” (website) Washington, DC. Available online: http://www.trb.org/StrategicHighwayResearchProgram2SHRP2/SHRP2FocusAreas.aspx, last accessed February 10, 2015.

- D.G. Aggelis, T. Shiotani, K. Kasai, Evaluation of grouting in tunnel lining using impact-echo, Tunnelling and Underground Space Technology, Volume 23, Issue 6, 2008, Pages 629-637, ISSN 0886-7798, https://doi.org/10.1016/j.tust.2007.12.001.