Bridge - Sounding

Target of Investigation

Sounding including chain drag and hammer sounding are mainly used to detect moderate to severe delamination in concrete structures. Chain drag is limited to horizontal surfaces, and hammer sounding can be used for a wider range of structures.

Description

The most common visual inspection methods used by State transportation departments and other bridge owners for detection of delamination in concrete bridge decks are chain drag and hammer sounding. The objective of these methods is to detect regions of the deck where the sound from dragging the chain or hitting with a hammer changes from a clear ringing sound (sound deck) to a somewhat mute and hollow sound (delaminated deck).(1)

Chain drag (figure 1) is a fast method for determining the location of moderate to severe delaminated area. The speed of chain drag varies with the level of deterioration of the deck and the experience of the inspector.

Hammer sounding (figure 2) is a slower and more appropriate method for smaller areas. Hammer sounding can be used in conjunction with chain drag in order to better define the size and extent of a delamination.

Physical Principle

Chain drag and hammer sounding can be categorized as crude vibrational modal tests. The operator drags chains or strikes a hammer on the deck, listening to the resulting sound. A clear ringing sound represents a sound deck while a mute/hollow sound represents a delaminated area.(1) The hollow sound is a result of the flexural oscillations of the delaminated section of the deck, creating a drum-like effect. Flexural oscillation of a delaminated area is typically in a 1 to 3 kHz range. This is within the audible range of a human ear.

Data Acquisition

Chain dragging is carried out using a custom-made tool consisting of one or more steel chains attached to a handle so that the operator can drag or swing the chains (figure 3).

For hammer sounding, any normal masonry hammer can be used (figure 4).

For chain dragging, the operator drags the chain on the deck while listening to the sound that the chain makes.(3) Delaminated areas will be detected based on the audible response of the deck. A clear ringing sound represents a sound deck while a mute/hollow sound represents a delaminated deck. The operator marks the locations that are perceived as delaminated.

Chain drag gives a more general indication of the delamination location. To get more accurate information about the size and shape of the delamination, hammer sounding can be conducted by tapping the concrete surface with an ordinary masonry hammer and listening for the response. Similar to the chain drag, a clear ringing sound represents a sound deck while a mute/hollow sound represents the delaminated deck. The operator marks the detected delaminated areas during the survey.

The figures below depict the testing procedure on a bridge deck followed by the markings of the delaminated regions on the deck (figure 5).

For complete testing procedures please refer to ASTM D4580-03(2007), Standard Practice for Measuring Delaminations in Concrete Bridge Decks by Sounding.(3)

Data Processing

Marked areas can be mapped on a grid or placed in drawing/mapping software for output; however, no processing of acquired data is needed.

Data Interpretation

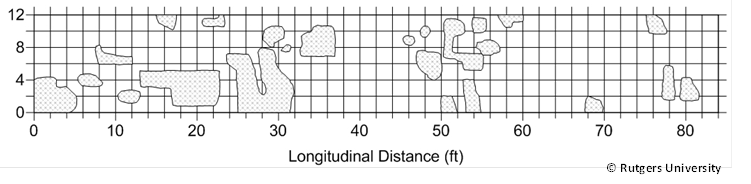

A typical map based on the chain drag/hammer sounding is shown in figure 6. The hatched areas correspond to the delaminated regions detected by chain drag and hammer sounding.

Advantages

- Rapid and well-established field collection method.

- Ability to identify severe to moderate delamination by a skilled technician.

- Field method is simple.

- Mapping is not difficult.

- Limited training required.

Limitations

- Labor intensive.

- Can become expensive testing due to traffic control.

- Cannot pick up the onset of delamination.

- Results are subjective and vary from one technician to the next.

- Must be performed when traffic noise is minimal.

- Generally ineffective for delamination detection on decks with asphalt overlays.

References

- Gucunski, N., et. al., Nondestructive Testing to Identify Concrete Bridge Deck Deterioration, Report S2-Ro6A-RR-1, SHRP2 Renewal Research, Transportation Research Board, 2013.

- Gucunski, N., et.al., Comprehensive Bridge Deck Deterioration Mapping of Nine Bridges by Nondestructive Evaluation Technologies, Project SPR-NDEB(90)-8H-00, Center for Advanced Infrastructure and Transportation, Rutgers University, January, 2011.

- ASTM, “Standard Practice for Measuring Delaminations in Concrete Bridge Decks by Sounding,” D4580-03, ASTM International, West Conshohocken, PA, 2007.

- Gucunski, N., “NDT to Identify Concrete Bridge Deck Deterioration,” Pacific Northwest Bridge Inspectors Conference, Portland, Oregon, April, 2013.