Pavements - Half-Cell Potential (HCP)

Target of Investigation

Half-cell potential (HCP) testing detects the presence of actively corroding reinforcing steel in concrete pavements.(1) HCP measurements can be used for in-service evaluation of reinforced concrete at any time during pavement life when an electrical connection to the reinforcing steel can be made.(2)

Description

HCP measurements are based on the coexistence of corroding areas (anodic half-cells) and noncorroding areas (cathodic half-cells). Measurements are taken of potential differences (voltages) across steel–concrete interfaces. The HCP measuring system is electrically connected to steel reinforcement in the concrete. A portable half-cell electrode usually a copper–copper sulphate (Cu/CuSO4) standard reference, is placed on the surface of the concrete.(3) The difference in potential between the reinforcement and the half-cell probe is measured; these measurements are taken in a grid pattern on the pavement to generate a spatial distribution of the corrosion potential. The difference in potential changes with the changing corrosion state of the reinforcing steel; thus, changes can be indicators of the corrosion state of the reinforcement.(4) Using empirical comparisons, the measurements can be linked to the probability of active corrosion.(3)

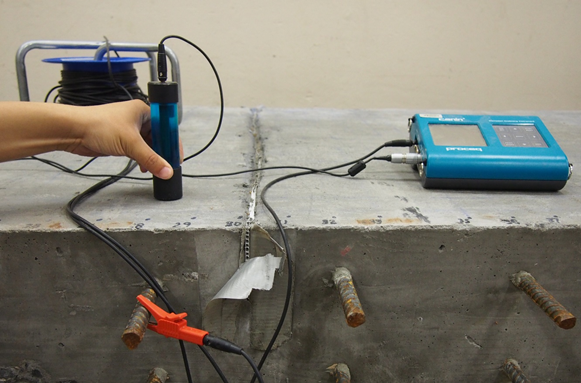

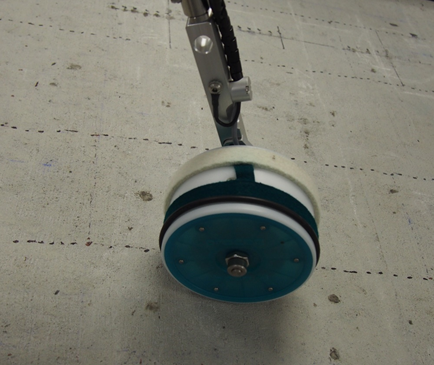

HCP test equipment includes a high-impedance voltmeter or data recorder and Cu/CuSO4 (or similar) reference electrode. The positive terminal of the voltmeter is connected to the reinforcing steel of the structure, and the negative terminal is connected to the reference cell.(4) Different probes are available, including Cu/CuSO4 rods (figure 1) and rolling electrodes (figure 2), depending on the application. Rolling probes are better suited for rapid scanning of large, horizontal areas.

Source: FHWA.

Source: FHWA. Source: FHWA.

Source: FHWA.Physical Principle

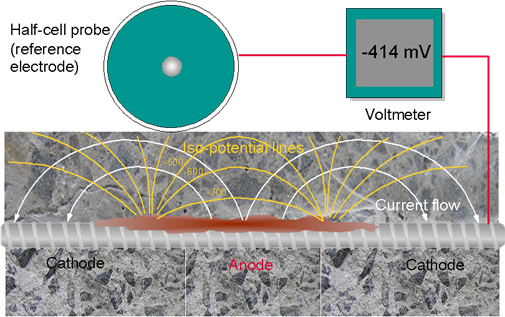

The corrosion of steel in concrete is similar to the electrochemical mechanism of the corrosion of a metal in an electrolyte. This likeness implies that separate anodic and cathodic processes take place simultaneously on the same metal surface. At the anodic site, iron is dissolved and then oxidized into iron ions, leaving electrons in the steel. At the cathodic site, the oxygen is reduced, and hydroxyl ions are produced.(5) This electrochemical process generates an electrical field.(5) The potential of this field is measured using a high-impedance voltmeter and reference electrode, where the positive terminal of the voltmeter is connected to the reinforcing steel of the structure and the negative terminal is connected to the reference electrode (figure 3). The reference electrode is usually galvanically connected to the concrete surface using a wet sponge.(6) The input impedance of the voltmeter should be in the range of 106 to 109 Ω.(6)

© 2015 N. Gucunski, Rutgers University.Note: Isopotential lines are measured in millivolts.

© 2015 N. Gucunski, Rutgers University.Note: Isopotential lines are measured in millivolts.Data Acquisition

The following is a summary of the HCP data collection procedure described in ASTM C876-09, Standard Test Method for Corrosion Potentials of Uncoated Reinforcing Steel in Concrete:(2)

- Lay out a grid on the pavement.

- Electrically connect the reinforcing steel to the positive lead of the voltmeter by doing the following:

- Locate the steel using a rebar locator, drill down to the reinforcement, and connect a lead wire to the steel using a self-tapping screw drilled into the rebar.

- Ensure that all measurement locations are electrically continuous with this screw.

- If required, use multiple screws and corresponding measurement areas to cover the entire survey area.

- Electrically connect the reference electrode to the negative lead of the voltmeter.

- Wet the contact sponge of the reference electrode to ensure good electrical contact with the concrete pavement by doing the following (prewetting can also be done, if conditions allow):

- Wet the entire deck surface or testing locations, but make sure no free surface water remains between test locations before taking measurements.

- Place a prewetted sponge on each test location before taking measurements, and leave the sponge in place for the duration of collection at that location.

- Place the reference electrode on the test point and record the potential measurement (by hand or with the data acquisition instrument) after the voltage measurement has stabilized.

- Move to the next test location and repeat the data collection procedure; using a rolling electrode probe allows the probe to remain in contact with the surface while moving from one test location to the next.

- After testing is complete, patch all tapped locations.

Data Processing

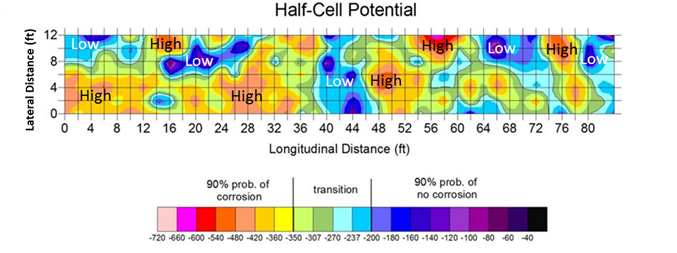

Typically, no operator processing of HCP data is performed, and the results are visualized as the measurements are taken.(6) Data-processing software is usually included with the equipment. The data are plotted in a straightforward way, such as in a contour map, using the spatial coordinates of the measurements to show areas of the reinforcing steel with high probabilities of active corrosion, low probabilities of active corrosion, and transition zones that span the measurements in between these potentials (figure 4).(6)

© 2015 Rutgers CAIT.1 ft = 0.3 m.

© 2015 Rutgers CAIT.1 ft = 0.3 m.Typically, areas with potentials greater than −200 mV have a 90-percent probability of no active corrosion, and areas with potentials less than −350 mV have a 90-percent probability of active corrosion. Areas with potentials between these values, however, have an uncertain probability of active corrosion.(2) For each structure, the potential thresholds need to be adjusted based on the structure’s construction and maintenance history as well as conditions that exist during measurement.(6)

Data Interpretation

HCP data should be interpreted by engineers or specialists in corrosion activity and concrete materials. In addition to HCP data, other methods (e.g., electrical resistivity, depth of carbonation, chloride contents, delamination surveys, rate of corrosion, environmental conditions) should be used to determine the corrosion activity of steel reinforcement and its probable effect on the service life of the pavement.(2)

Advantages

Advantages of using HCP measurements include the following:

- Indicative of the probability of active corrosion of reinforcing steel.

- Rapid and easy to use.

- Effective over large areas.

- Minimal training required for data collection.

- Straightforward data processing.

Limitations

Limitations of using HCP measurements include the following:

- Analysis requires experienced personnel and correlation with other information to formulate conclusions about corrosion activity of reinforcing steel.

- Corrosion of steel is not directly measured.

- Overlays, paint, and other coatings may prevent adequate electrical connectivity between the device and pavement.

- Measurements cannot be taken for epoxy-coated reinforcing steel.

- Electrical connectivity to reinforcing steel is required throughout the test area.

- Specialized procedures may be required if the concrete resistivity is too high for the normal procedures (e.g., because of dryness).(2)

References

- Marks, V.J. (1977). Detection of Steel Corrosion in Bridge Decks and Reinforced Concrete Pavement, Report No. Project HR-156, Iowa Department of Transportation, Ames, IA.

- ASTM C876-015 (2015). “Standard Test Method for Corrosion Potentials of Uncoated Reinforcing Steel in Concrete.” Book of Standards 03.02, ASTM International, West Conshohocken, PA.

- Gucunski, N., Imani, A., Romero, F., Nazarian, S., Yuan, D., Wiggenhauser, H., Shokouhi, P., Taffee, A., and Kutrubes, D. (2013). Nondestructive Testing to Identify Concrete Bridge Deck Deterioration, Report No. S2-R06A-RR-1, Transportation Research Board, Washington, DC.

- Boyd, S.R. and Frauss, P.D. (2006). Highway Concrete Technology Development and Testing: Volume V – Field Evaluation of Strategic Highway Research Program (SHRP) C‑206 Test Sites (Bridge Deck Overlays), Report No. FHWA-DR-02-086, Federal Highway Administration, Washington, DC.

- Federal Highway Administration. (2016). “Nondestructive Evaluation Laboratory: Equipment.” (website) Washington, DC. Available online: https://highways.dot.gov/laboratories/nondestructive-evaluation-laboratory/nondestructive-evaluation-laboratory-overview, last accessed April 15, 2016.

- Gucunski, N., Romero, F., Kruschwitz, S., Feldmann, R., and Parvardeh, H. (2011). Comprehensive Bridge Deck Deterioration Mapping of Nine Bridges by Nondestructive Evaluation Technologies, Report No. SPR-NDEB(90)-8H-00, Center for Advanced Infrastructure and Transportation, Piscataway Township, NJ.