Tunnel - Ground Penetrating Radar (GPR)

Target of Investigation

Ground penetrating radar (GPR) can be used for condition assessment of tunnel linings and other concrete members of concrete, tile-lined concrete, and shotcrete tunnels.(1) For condition assessment of concrete members, GPR can be used to detect the following:

- Rebar locations.

- Moisture intrusion and corrosion-related problems.(1)

- Subsurface defects, such as tile debonding, voids, and delaminations.(1)

Description

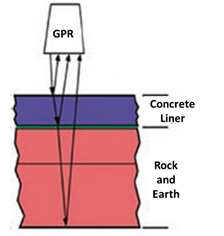

GPR testing is a widely used nondestructive evaluation technique for detecting subsurface structural elements and anomalies in structures. GPR operates by sending discrete electromagnetic wave pulses into a structure and then capturing the reflections from layer interfaces (e.g., objects and defects) within the structure. Collected data are processed and analyzed to create a condition map of the structure or an image of the subsurface structure, including rebars and defects.

Two types of GPR systems are available: air coupled and ground coupled. Air-coupled systems have antennas that are positioned above the surface of the structure and can be mounted on vehicles for relatively fast scanning (figure 1). Ground-coupled systems have antennas that must remain in contact with the surface while collecting data (figure 2). Air-coupled GPR systems evaluate tunnels faster than ground-coupled systems. Air-coupled systems can locate defects within 1 ft (0.3 m) of their actual locations and are generally used as a scanning tool to indicate where to perform more indepth testing with other systems, such as ground-coupled radar systems.(1) Although ground-coupled systems are slower, they provide deeper penetration and higher resolution data. Groundcoupled systems can determine depth of a defect within 10 percent of its actual depth, and when reference cores are used, results are within 5 percent of a defect’s actual depth. These systems are also able to detect defects up to 4 ft (1.2 m) deep when the defects contain significant air pockets or moisture.

A. Moving platform with GPR.

B. Boom and GPR.

Figure 1. Photos. Air-coupled GPR system mounted on a truck boom.(1)

Figure 2. Photo. Ground-coupled GPR system.(1)

A typical GPR system has the following components:

- Data collection module.

- Computer controller.

- Air- or ground-coupled antenna.

- Distance indicator.

- Survey vehicle (air coupled).

- Scanning apparatus to which the system is mounted (ground coupled) (optional).

Physical Principle

GPR operates by sending discrete electromagnetic wave pulses (with a frequency range of

100–5,000 MHz) into a structure and then capturing the reflections from layer interfaces or other reflectors within the structure. Radar obeys the laws governing reflection and transmission of electromagnetic waves and is affected by the electrical properties of the material: conductivity and the dielectric constant.(1)

Air-Coupled GPR

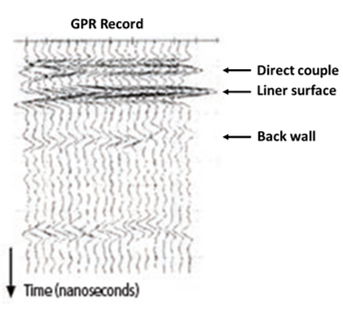

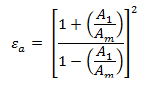

As shown in figure 3, the largest peak in an air-coupled GPR reading is the reflection from the surface. The amplitudes before the direct couple are internally generated noise, and they should be removed from the trace prior to signal processing. Reflections that occur after the surface echo represent significant interfaces below the surface, and the measured travel time is related to the depth of the layer or defect. Air-coupled GPRs can measure surface dielectric constants by comparing reflected signals from the liner surface and a steel plate at the same distance. The equation for calculating the dielectric constant is presented in figure 4. Normal concrete usually has a dielectric value between 8 and 12. Values above this range indicate excessive moisture; values below this range indicate significant air voids.(1)

A. GPR propagation and reflection.

B. Multiple GPR A-scans.

Figure 3. Illustrations. Signal from an air-coupled GPR.(2)

Where:

εa = dielectric of the liner surface.

A1 = amplitude of reflection from the surface.

Am = amplitude of reflection from a large metal plate on the surface.

Ground-Coupled GPR

The physical principles of ground-coupled GPR systems are similar to those of air-coupled GPR systems. Although slow compared to air-coupled systems, ground-coupled systems provide better depth penetration and a higher number of data readings. Thus, ground-coupled systems are much better suited for indepth data collection and defining subsurface interfaces or defects.

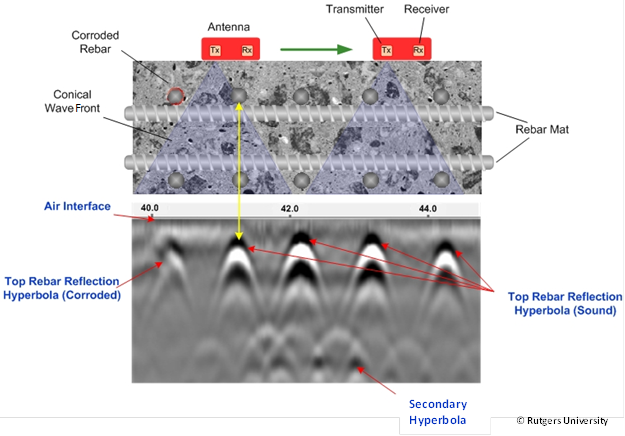

A GPR signal attenuates as it travels in a structure. Signal attenuation depends on the geometric attenuation, signal scattering, reflections, and thermal losses. Two-way travel time and reflection amplitudes are recorded with a receiver antenna. When the measurements are made over sequential survey points, they can be viewed as a GPR B-scan or profile (figure 5). The thickness of a layer within the structure can be calculated from two-way travel time. Rebars are seen as bright hyperbolas. Amplitudes of reflections from top-layer rebars are normalized with respect to concrete in good condition to plot the attenuation as a condition map. A deterioration threshold value of the attenuation can be established using ground truth (cores or other nondestructive test methods) following interpretation of the data.(3) Heterogeneities, such as voids and water, have different dielectric values and densities from the concrete material; GPR can show irregular reflections caused by these heterogeneities.

Figure 5. Image. Attenuation of a GPR signal.(4)

Data Acquisition

Air-Coupled GPR

Air-coupled GPR manufacturers recommend following their system-specific testing procedures when collecting data. These procedures are available in the user manuals supplied by the manufacturers. For tunnel operations, the following are also recommended:(1)

- Before collecting data on a tunnel lining, personnel should collect at least 50 waveform traces on a metal plate measuring at least 16 ft2 (4.87 m2). The operating height of the antenna should be between 12 and 18 inches (0.3 and 0.45 m). The resulting data will be used to calculate the surface dielectric.

- During data collection on the tunnel lining, data should be collected with 1 ft (0.3 m) or less between survey lines.

- Within a tunnel, global positioning systems cannot be used, so other methods (e.g., survey wheels) should be used.

Ground-Coupled GPR

As with air-coupled GPR systems, manufacturers of ground-coupled GPR systems recommend following their system-specific testing procedures when collecting data. These procedures are available in the user manuals supplied by the manufacturers.

Data Processing

Data preprocessing, processing, and interpretation can be done using analysis software. Preprocessing operations, which do not change the signal content of the original data, include data channel splitting, data scaling, data reversing, and zero-level correction. Processing operations consist mainly of filtering operations and amplitude and dielectric value calculations. These operations are fully reversible and changeable. The primary objective of processing is to make GPR data more informative and easy to interpret. Software can be used to “pick” individual rebars for condition assessment analysis. Figure 6 shows raw, preprocessed, and processed data.

A. Raw GPR data.

B. Preprocessed GPR data.

C. Processed GPR data.

Figure 6. Screenshots. Raw, preprocessed, and processed GPR data.(1)

Software can calculate the depths of suspected defects using the two-way travel time between the anomaly and the antenna, the x-coordinate of the pick (selected rebar) within the profile, the surface dielectric values, and the wave velocity within the concrete. The signal attenuation at the top-layer rebar can also be calculated.

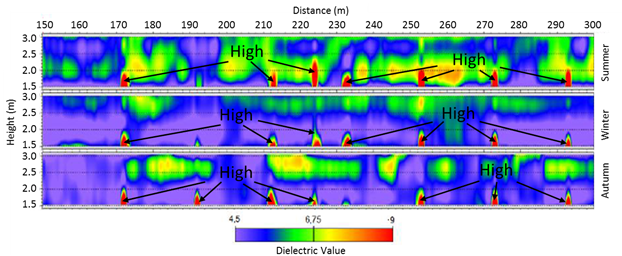

Data Interpretation

Data interpretation should be performed by personnel with extensive training and experience. The surface dielectric profiles can be stitched together to create color-coded dielectric surface maps for visualization of the tunnel lining’s condition. Figure 7 shows color-coded maps for dielectric values of a tunnel wall in summer, winter, and autumn. The attenuation of the signal at the top-layer rebar can represent the condition of the concrete because a corrosive environment (characterized by moisture, chlorides, rust, and cracks) will highly attenuate the signals.(5) A contour map of concrete condition (attenuation) can be created to present concrete deterioration.

1 m = 3.3 ft.

Figure 7. Contour map. Dielectric values of tunnel wall in summer, winter, and autumn.(1)

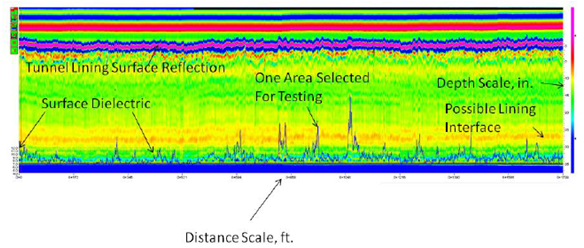

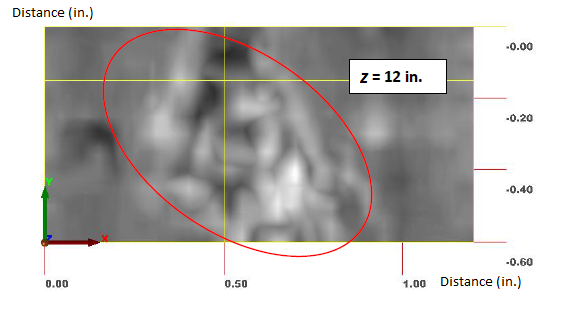

Suspected defects, such as voids, can also be detected as anomalies in GPR B-, D-, and C-scans. Voids tend to appear as pronounced, irregular bright-spot anomalies with higher amplitudes than the surrounding material. Internal thicknesses of voids are difficult to estimate because the bottoms of voids tend not to be imaged by GPR data.(6) Figure 8 shows one B-scan of a tunnel liner, from which the liner surface and layered interfaces can be recognized. The surface dielectric values along the B-scan are also presented in figure 8. Figure 9 shows an example of a void from a GPR C-scan.

1 inch = 25.4 mm; 1 ft = 0.3 m.

Figure 8. Image. Air-coupled GPR data showing subsurface anomalies and the surface dielectric value.(1)

z = depth.

1 inch = 25.4 mm.

Note: The circled area is approximately 24 by 20 inches (0.6 by 0.5 m).

Figure 9. Image. GPR C-Scan showing a potential void at a depth of 12 inches (0.3 m).(1)

Advantages

Advantages of GPR testing include the following:

- Well-established field data collection processes.

- Rapid test methods.

- Reliable and repeatable results.

Limitations

Limitations of GPR testing include the following:

- Defects (delamination and voids) are detectable only if they contain significant air pockets or are filled with water.(7)

- The presence of a potential delamination is inferred from the properties associated with advanced corrosion and the formation of corrosion products.

- Air-coupled GPR systems should not be relied on to determine the depths of defects.

- Extensive training and experience are required for operation, data processing, and data interpretation.

- Steel fibers in shotcrete and steel slag in some concrete prevent signal penetration.

- Salts in concrete (from deicing operations or seawater) may cause signal-penetration problems.

- External electromagnetic radiation (from cell phone, radio, and television antennas) can cause signal degradation.

- Global positioning systems cannot be used within the confines of the tunnel.

References

- Wimsatt, A., White, J., Leung, C., Scullion, T., Hurlebaus, S., Zollinger, D., Grasley, Z., et al. (2014). Mapping Voids, Debonding, Delaminations, Moisture, and Other Defects Behind or Within Tunnel Linings, Report No. S2-R06G-RR-1, Transportation Research Board, Washington, DC.

- Arnold, J.A., Gibson, D.R.P., Mills, M.K., Scott, M., and Youtcheff, J. (2011). “Using GPR to Unearth Sensor Malfunctions.” Public Roads, 74(4), Federal Highway Administration, Washington, DC.

- Gucunski, N., Feldmann, R., Romero, F., Kruschwitz, S., Abu-Hawash, A., and Dunn, M. (2009). “Multimodal Condition Assessment of Bridge Decks by NDE and its Validation.” Proceedings of the 2009 Mid-Continent Transportation Research Symposium, Iowa State University, Ames, IA.

- Gucunski, N., Imani, A., Romero, F., Nazarian, S., Yuan, D., Wiggenhauser, H., Shokouhi, P., Taffee, A., and Kutrubes, D. (2013). Nondestructive Testing to Identify Concrete Bridge Deck Deterioration, Report No. S2-R06A-RR-1, Transportation Research Board, Washington, DC.

- Dinh, K., Gucunski, N., Kim, J., and Duong, T.H. (2016). “Understanding depth-amplitude effects in assessment of GPR data from concrete bridge decks.” NDT&E International, 83, pp. 48–58, Elsevier, Amsterdam, Netherlands.

- Parkinson, G. and Ekes, C. (2008). Ground Penetrating Radar Evaluation of Concrete Tunnel Linings, 12th International Conference on Ground Penetrating Radar, Birmingham, United Kingdom.

- Heitzman, M., Maser, K., Tran, N.H., Brown, T., Bell, H., Holland, S., Ceylan, H., Belli, K., and Hiltunen, D. (2013). Nondestructive Testing to Identify Delaminations Between HMA Layers, Report No. S2-R06D-RR-1, Transportation Research Board, Washington, DC.