Pavements - Georgia Faultmeter (GFM)

Target of Investigation

A faultmeter is used to measure joint faulting and lane–shoulder dropoffs in jointed concrete pavements.

Description

Faulting, which is the difference in elevation on either side of a joint or crack in a concrete surface, is usually caused by pumping, settlement, curling, and warping. Faulting is noticeable when the average difference in elevations of a pavement section reaches about 2.54 mm (0.1 inches). Faulting contributes to the roughness that adversely affects the ride quality of a pavement. Lane–shoulder dropoff refers to the difference in the elevation between the edge of a slab of pavement and the outside shoulder, which typically occurs when the outside shoulder settles. A faultmeter is employed to measure the magnitude of the faulting or lane–shoulder dropoff. As shown in figure 1, the faultmeter is portable and supplies a digital readout with the push of a button located on the carrying handle. The unit measures faulting in about 1 s, then the measurement is saved on the display so that the operator can read it in a safe manner (i.e., off the road).

Source: FHWA.

Source: FHWA.Physical Principle

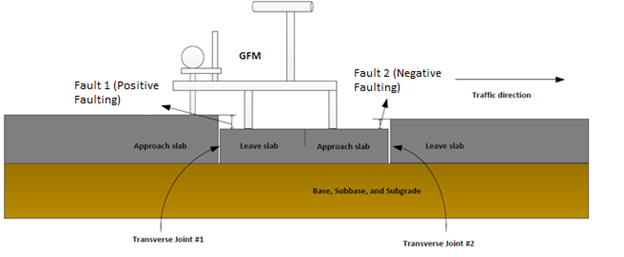

The Georgia Department of Transportation’s Office of Materials and Research originally designed and developed the Georgia Faultmeter (GFM).(2) There are two versions of the GFM. Manual GFMs use dial gauges to determine the difference between the elevations of the two sides of a crack or joint (figure 2), whereas automated GFMs use linear variable differential transformers to calculate the difference.(3) Any slab that is higher on the approach side of the joint than the leave side registers a positive faulting number. If the slab on the leave side of the joint is higher than the approach side, the meter gives a negative reading.

Source: FHWA.

Source: FHWA.Data Acquisition

The step-by-step process for collecting data with a faultmeter is provided in the Distress Identification Manual for the Long-Term Pavement Performance Program.(1) To begin the process, the joint must be centered between the guidelines on the side of the meter. The legs of the faultmeter’s base should be set on the slab in the direction of traffic on the leave side of the joint. The measuring probe will contact the slab on the approach side. Three measurements are taken at each testing location; the operator chooses one value to use. This representative value is recorded to the nearest millimeter. In cases of a widened lane, the measurement should be taken approximately 0.3 m (1 ft) from the edge of the slab and 0.75 m (2.5 ft) from the outside edge of the edgeline. When anomalies, such as patching, spalling, and corner breaks, are encountered, the faultmeter should be offset to avoid such anomalies in the readings. The maximum offset is 0.3 m (1 ft). A null value should be recorded and entered into the database when the surveyor is unable to take a measurement from an anomaly. Lane–shoulder dropoffs are measured as the difference in elevation, between the pavement surface and the adjacent shoulder surface. Measurements are taken at the beginning of the test section and at intervals at the lane–shoulder interface or joint. Where no lane–shoulder dropoff exists, a measurement of 0 is recorded.

Data Processing

Data from a faultmeter do not require much processing. The readings and test locations should be recorded in a tabular form.

Data Interpretation

If the approach slab is higher than the departure slab, the faulting should be recorded as positive; if the approach slab is lower than the departure slab, the faulting should be recorded as negative.

Advantages

Advantages of faultmeters include the following:

- Operation is quick and easy at each test location.

- Data are easy to process and interpret.

Limitations

Limitations of faultmeters include the following:

- Lane closures and traffic control are needed.

- Measurements for large sites are time consuming.

References

- Miller, J.S. and Bellinger, W.Y. (2014). Distress Identification Manual for The Long-Term Pavement Performance Program (Fifth Revised Edition), Report No. FHWA-HRT-13-092, Federal Highway Administration, Washington, DC.

- Stone, J. (1991). Georgia Digital Faultmeter, Report No. FHWA-GA-91-SP9010, Federal Highway Administration, Washington, DC.

- Agurla, M. and Lin, S. (2015). Long-Term Pavement Performance Automated Faulting Measurement, Report No. FHWA-HRT-14-092, Federal Highway Administration, Washington, DC.