Tunnel - Dye Penetrant Testing (DPT)

Target of Investigation

The primary application of penetrant testing (DPT) in tunnels is detecting and monitoring surface cracks in steel structural members, gusset-plate connections, and welded details in the field. Common applications of the technology include indicating surface porosity, detecting hairline cracks at fatigue-prone details, and verifying visual inspection results.

Description

DPT is a nondestructive method for crack detection in metals. DPT is a process by which a liquid dye is applied to the surface to be inspected; this dye seeps into cracks and other voids or depressions in the surface. The surface is then wiped clean, removing all the excess dye. Dye that has penetrated a crack is not removed by cleaning and emerges from the crack because of capillary action.

This process results in a visible indication of the crack on the surface.(1,2) Subsurface cracks or volumetric weld defects (porosity, lack of fusion, slag inclusions, etc.) cannot be detected using DPT. Access to the defect is required to preclean the surface, apply penetrant and developer, and visually observe results. Areas that are not easy to access or where other members interfere with access to the surface may be difficult to assess with DPT.

To ensure the indication is easy to visually observe, the color contrast between the liquid dye and the surface undergoing inspection may be enhanced. For typical field inspections, this contrast is accomplished by applying a developer to the surface after it has been cleaned. Developers are typically white; the liquid dye is typically red. The color contrast between the white developer and the red dye ensures an inspector can easily observe crack indications.

Another method for improving the contrast between an indication and the surface being inspected is the use of fluorescent dye. A fluorescent dye contains particles that, when illuminated with ultraviolet light, emit intense visible spectrum light. This fluorescent dye improves the light intensity contrast between the fluorescing crack indicator and the surface under inspection, which is not fluorescing. Generally, dark ambient-light conditions are required to observe the light contrast between the dye and the surface being inspected.(1,2) Consequently, fluorescent DPT is not commonly used for bridges in the field.

Physical Principle

DPT works on the physical principle of capillary action. Capillary action (or capillary motion) describes the ascent of a liquid along a surface in opposition to gravity. This ascent occurs when the adhesive forces between a liquid and a solid surface exceed the cohesive forces within the liquid itself. As a result, the liquid spreads along the solid surface and can overcome the gravitational forces to climb the surface in a vertical direction. For DPT, liquid confined within a crack emerges on the surface of the material, forming an indication of the presence of the crack on the surface of the material.

Data Acquisition

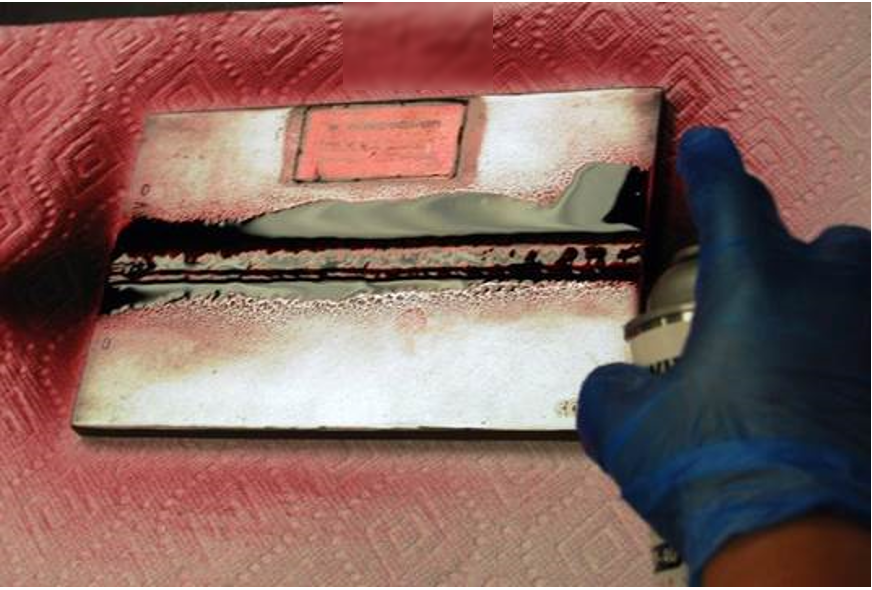

Figure 1 through figure 4 illustrate several steps in the procedure. The procedure begins with cleaning the surface of the material to remove any existing coating, debris, and foreign material from the area to be assessed. Once the surface has been fully cleaned, a colored dye penetrant is applied in a thin coating on the surface (figure 1). The colored dye is allowed to rest on the surface for a dwell period, lasting 10–30 min. This dwell period allows the dye to penetrate any discontinuities (e.g., cracks) in the surface.

Figure 1. Photo. Applying dye penetrant to the surface.

Once the desired dwell time has passed, the surface is thoroughly cleaned with a cloth moistened with a solvent to remove all dye from the surface (figure 2).

Figure 2. Photo. Cleaning the surface.

Developer is then applied to the surface in a thin, even coat (figure 3).

Figure 3. Photo. Applying developer.

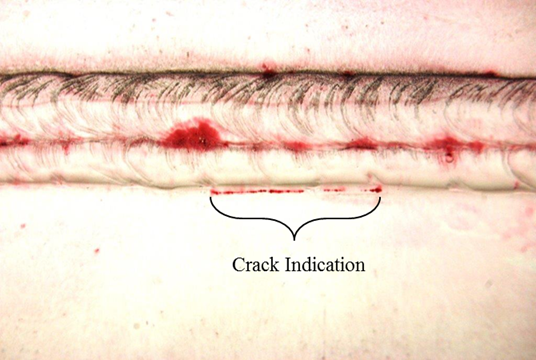

An additional dwell time of 5–15 min allows the penetrant the time necessary to emerge from cracks in the surface and form an indication (figure 4).

Figure 4. Photo. Crack indication.

Data Processing

The data produced from a DPT inspection are visible indications on the surface of the material being tested. Indications are photographed and documented in notes or an inspection report.

Data Interpretation

Data interpretation consists of visual observations of the penetrant emerging from features on the surface of the material. Linear indications generally indicate cracks. Nonrelevant indications are produced when dye becomes entrapped in a surface feature that is not a crack and emerges through the developer. Inadequate surface cleaning can result in nonrelevant indications. For example, dye emerging from debris on the surface or from undercoatings that have not been fully removed is a nonrelevant indication. Welds with surface relief owing to undercut, surface porosity, or a rough weld bead may also produce nonrelevant indications.

Advantages

Advantages of DPT include the following:

- Simple to apply; minimal training required.

- Relatively easy data interpretation.

- Low cost.

Limitations

Limitations of DPT include the following:

- Necessitates removing all coatings, which compromises corrosion protection.

- Involves extensive surface preparation, potentially producing hazardous materials when lead paints are present.

- Requires long time intervals to apply (approximately 30–60 min).

- Entails long dwell times (10–30 min for penetrant to seep into cracks and 5–15 min for penetrant to appear through the developer).

- Detects only surface-breaking cracks.

References

- ASTM E1417/E1417M-16. (2012). “Standard Practice for Liquid Penetrant Testing.” Book of Standards 03.03, ASTM International, West Conshohocken, PA.

- ASTM E165-12. (2012). “Standard Practice for Liquid Penetrant Examination for General Industry.” Book of Standards 03.03, ASTM International, West Conshohocken, PA.