Bridge - Displacement Gauge (DG)

Target of Investigation

A displacement gauge can be used to measure the following:

- Absolute displacement or deflection of a structural surface from a reference surface or the ground.

- Relative displacement of two surfaces.

Description

A displacement gauge is used to measure the distance between an object and a reference position. Displacement gauges manufactured based on different physical principles can have different measuring ranges, accuracies, and usage environments to serve applications with different purposes.

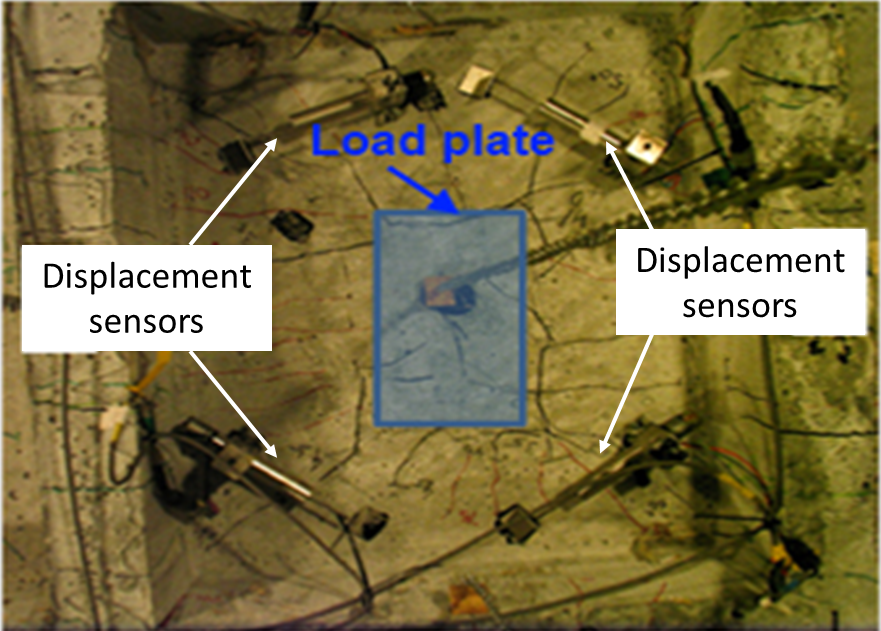

Measurements using displacement gauges can be classified into two broad categories: noncontact measurements using light or sound waves and contact measurements performed in direct contact with the target.(1) Figure 1 shows an example using contact-type displacement sensors to measure the crack opening of a concrete structure under load.(2)

Figure 1. Photo. Displacement sensors used to measure crack openings.(2)

Physical Principle

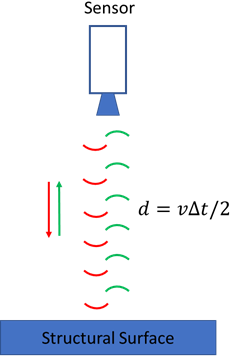

Displacement gauges have been developed based on different physical principles. The noncontact type of displacement gauge is usually developed based on propagation and reflection of light or sound waves. For example, displacement may be measured based on the two-way travel time of either ultrasonic waves or laser beams. Displacement may also be based on the principle of triangulation to detect the difference in position of reflected laser beams on the light-receiving element. Figure 2 shows the physical principle of noncontact displacement sensors using twoway travel time. Other noncontact displacement gauges use different physical principles. For example, eddy current–based displacement sensors measure voltage changes as a result of changes in the interaction of the magnetic field owing to different distances between the probe and target.

d = distance between sensor and structural surface; v = speed of sound waves; Δt = two-way travel time of signal.

Figure 2. Illustration. Physical principle of noncontact displacement measurement using ultrasound.

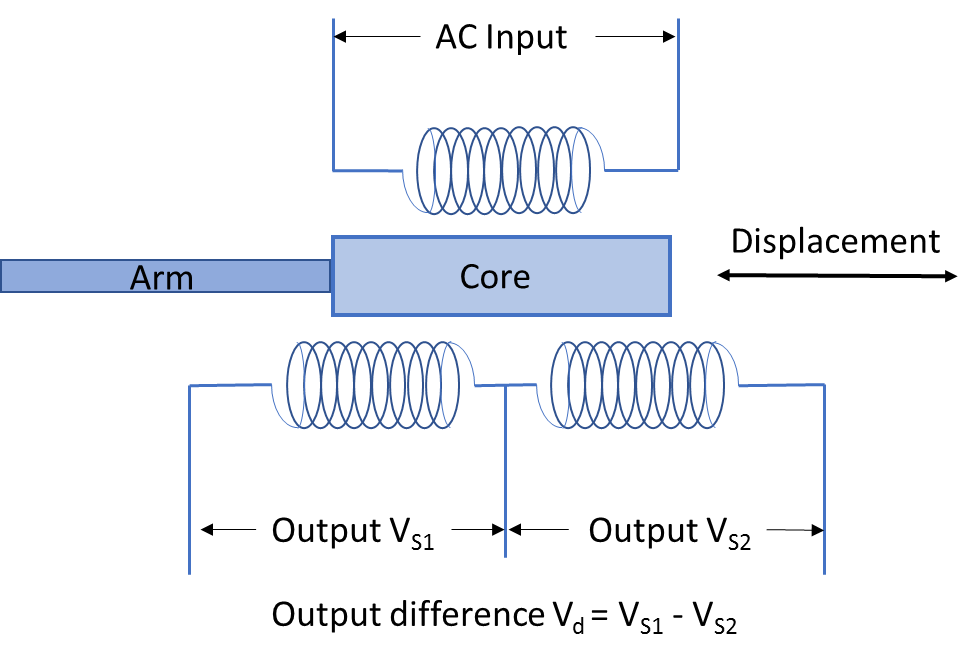

Contact-type displacement gauges usually convert displacements between the two anchorages of the gauge to either an electrical or mechanical signal (spring force). For example, figure 3 shows the physical principle of a linear variable differential transformer, which converts displacement to an electrical voltage. The movable soft iron core is attached to the measured surface by the arm. The device is attached to the reference surface. An alternating current (AC) voltage is supplied to the primary winding. Two voltages, VS1 and VS2, are obtained at the two secondary windings. Vd, the output voltage between the two secondary windings, is the difference between VS1 and VS2 and linearly related to the displacement of the soft iron core. Other contact types of displacement gauges can be developed based on different physical principles.

Figure 3. Illustration. Physical principle of a linear voltage differential transformer.

Data Acquisition

Data gathered by a displacement gauge can include two-way travel time, voltage, resistance, or mechanical force or moment. Data acquisition systems that capture signals from a displacement gauge can be an interferometer interrogator, ohmmeter with milliohm sensitivity to measure the resistance of the gauge, or dial gauge. Displacement gauges can be installed on a permanent basis to monitor an area where differential settlement is anticipated.

Data Processing

A displacement gauge produces a voltage/resistance, light signal, or force/moment, which changes as a result of changing displacement. The change can be converted to the displacement by a calibration factor. Thus, little data processing is required.

Data Interpretation

The measured displacement can be used to determine if the displacement between the target surface and the reference surface is within the acceptable limits.

Advantages

Advantages of displacement gauges include the following:

- Simple application.

- Easy data interpretation.

- Continuous monitoring of a displacement.

Limitations

Limitations of displacement gauges include the following:

- Requires surface access for contact measurement.

- Requires surface preparation for contact measurement.

References

- KEYENCE. “What are Displacement Sensors (Displacement Gauges) and Dimension Measurement Systems?” (website) Itasca, IL. Available online: https://www.keyence.com/ss/products/measure/measurement_library/basic/products_info/, last accessed October 4, 2018.

- Federal Highway Administration. (2016). “Design Guide for Precast UHPC Waffle Deck Panel System, including Connections.” (website) Washington, DC. Available online: https://www.fhwa.dot.gov/hfl/partnerships/uhpc/hif13032/chap01.cfm, last accessed August 2, 2018.