Tunnel - Crack Propagation Gage (CPG)

Target of Investigation

After a fatigue crack resulting from applied loads has been visually detected in a material (such as steel girders, eyebars, and truss members), crack-propagation gauges (CPGs) are used to measure the crack, determine if it is growing, and monitor the rate of extension.

CPGs can also be used to monitor localized areas of structure members where cracking is likely to develop. Thus, the gauge can be used as a crack-detection tool that continuously monitors the area to determine if a crack develops.

Description

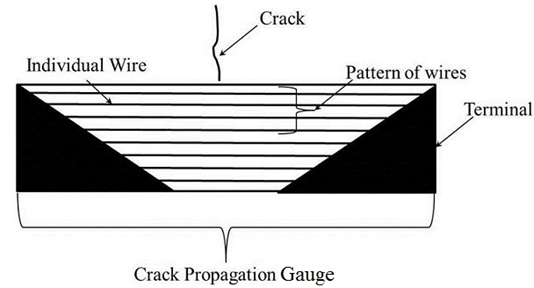

A CPG consists of a series of conductive tracks etched into a polymer substrate. The gauge is bonded to the surface of a specimen in the area of the crack tip such that growth of the crack will result in individual tracks in the gauge being fractured, affecting the resistance of the gauge.

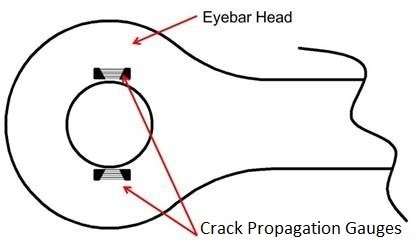

Figure 1 shows a schematic diagram of two CPGs mounted on the surface of an eyebar. The gauges are mounted on the eyebar head in the area where cracks initiating at the bore of the eyebar would be expected to grow. In this way, the gauges act as crack-detection sensors that produce resistance changes if a crack develops in the area under the gauge.

Figure 1. Illustration. Two CPGs mounted on an eyebar head.

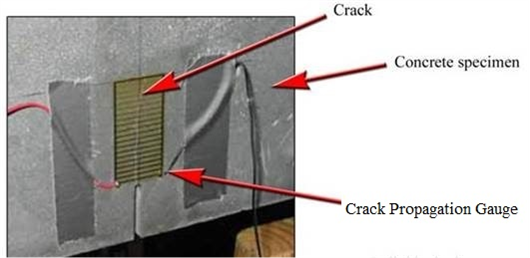

CPGs are available in a variety of sizes and shapes. Circular or semicircular gauges are produced for monitoring cracks initiating at bolt holes. Rectangular gauges (figure 2) are available in a variety of different sizes and are typically used for monitoring cracks in plates. Gauges are bonded to surfaces using an adhesive.

Figure 2. Photo. A CPG bonded to a specimen surface.

Physical Principle

CPGs are used to measure the growth of a surface-breaking crack. The sensor consists of a pattern of conductive tracks etched into a nonconductive polymer substrate. The gauge is bonded to the specimen surface at the tip of a crack (figure 3). When the crack length increases, the individual tracks in the sensor gauge are fractured, causing the resistance of the gauge to increase. A simple voltage or resistance measurement across the terminals on the gauge indicates the number of tracks that are fractured, and these changes are interpreted to determine crack growth.(1)

Figure 3. Illustration. CPG placement.

Data Acquisition

A CPG produces data in the form of voltage or resistance measurements. The resistance of the gauge increases when individual conductive tracks are fractured by a crack propagating across the gauge. Instrumentation to read a CPG can be as simple as an ohmmeter with milliohm sensitivity to measure the resistance of the gauge directly. Common data acquisition systems monitor the voltage output of a gauge. Data are typically collected over weeks, or even years, depending on the anticipated rate of crack growth. CPGs can be installed on a permanent basis to monitor an area where cracks are anticipated.

Data Processing

A CPG produces a voltage or resistance measurement that changes as a result of crack propagation; therefore, little data processing is required.

Data Interpretation

CPGs provide data via changes in the resistance of the gauge. These changes are interpreted to determine the length of the crack extension.

Figure 4 illustrates the typical output of a CPG. The gauge pattern shown has six conductive tracks extending between terminals at each end. Voltage or resistance measurements across these terminals indicate the number of tracks that have fractured. As the crack propagates in the material being tested, the conductive tracks of the CPG are fractured, resulting in an increase in the resistance between the terminals on the gauge.

Figure 4. Graph. Resistance changes in a CPG.

Advantages

Advantages of using CPGs include the following:

- Low cost.

- Simple application.

- Easy data interpretation.

- Continuous monitoring of crack growth.

Limitations

Limitations of using CPGs include the following:

- Can only be used on surface-breaking cracks.

- Requires surface access.

- Requires surface preparation.

- Needs to initially predict zones for crack growths.

References

- ASTM E647-13ae1. (2013). “Standard Test Method for Measurement of Fatigue Crack Growth Rates.” Book of Standards 03.01, ASTM International, West Conshohocken, PA.