Pavements - Circular Texture Meter (CTM)

Target of Investigation

Circular texture meters are laser-based devices for measuring the mean profile depth (MPD) of a pavement at a given location. MPD values obtained from a circular texture meter are highly correlated with mean texture depth (MTD) values and can replace volumetric measurement methods often used to determine MTD.

Description

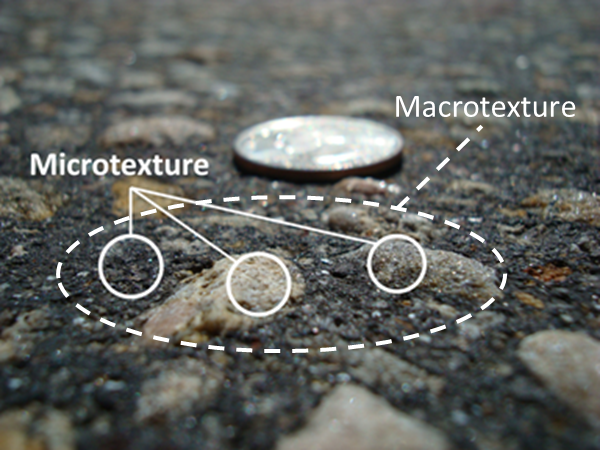

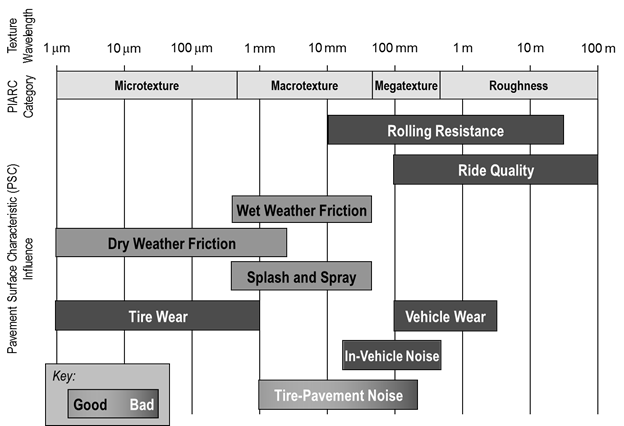

A pavement’s surface texture is related to many of its other characteristics. “Microtexture” includes surface textures with wavelengths of 0.001–0.5 mm (0.04–20 mils), and “macrotexture” includes surface textures with wavelengths of 0.5–50 mm (20 mils–2 inches) (figure 1).(1) Frictional characteristics of a pavement surface are related to both microtexture and macrotexture. Microtexture provides a gritty surface; it can accommodate films of water and produce good frictional resistance between the tire and the pavement. Macrotexture provides drainage channels for water expulsion between the tire and the pavement, allowing better tire contact with the pavement. Macrotexture facilitates improved frictional resistance and prevents hydroplaning.(2) Macrotexture is also related to the level of noise emitted by a pavement. Additionally, it has been used to identify the segregation of the asphalt layer.(3)

© 2013 The Transtec Group, Inc.

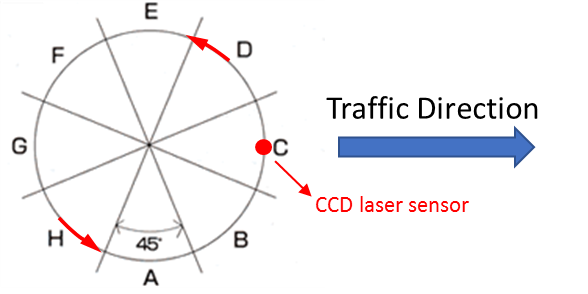

© 2013 The Transtec Group, Inc. Circular texture meters (figure 2) measure the profile of a circle by using a laser. A circle with 284 mm (11.2 inches) diameter is divided into eight equal segments with curved lengths of 111.5 mm (4.4 inches) (segments A–H in figure 3). The mean segment depth (MSD) is determined for each segment of the circle. The reported MPD is the average of all eight segment depths.

© 2009 AASHTO. B. Application of circular texture meter.

© 2009 AASHTO. B. Application of circular texture meter. Physical Principle

The circular texture meter has a charged coupled device (CCD) laser displacement sensor. A CCD is mounted on a rotating arm 80 mm (3.15 inches) above the pavement surface; the rotation of the arm moves the CCD in a circle with a diameter of 284 mm (11.2 inches). The arm is driven by a motor at a tangential velocity of 6 m/min (19.6 ft/min). The CCD takes a measurement 1,024 times per rotation, providing a sample spacing of 0.87 mm (0.034 inches). The MPD, the root mean square (RMS), or both are computed for each segment.

Source: FHWA.

Source: FHWA. Data Acquisition

ASTM E2157-15, Standard Test Method for Measuring Pavement Macrotexture Properties Using the Circular Track Meter, covers the procedure for obtaining and analyzing pavement macrotexture profiles using a circular texture meter.(6) The circular texture meter is placed on a dry, clean, and homogeneous area of the pavement surface. The circular texture meter is oriented with segments C and G in line with the direction of traffic (figure 3). A computer controls the data collection process and monitors, saves, and processes the collected data. As soon as the measurement is initiated via the computer, a direct current motor drives the arm for a full 360degree revolution, records the data, and estimates the profile of each of the eight segments for analysis.

Data Processing

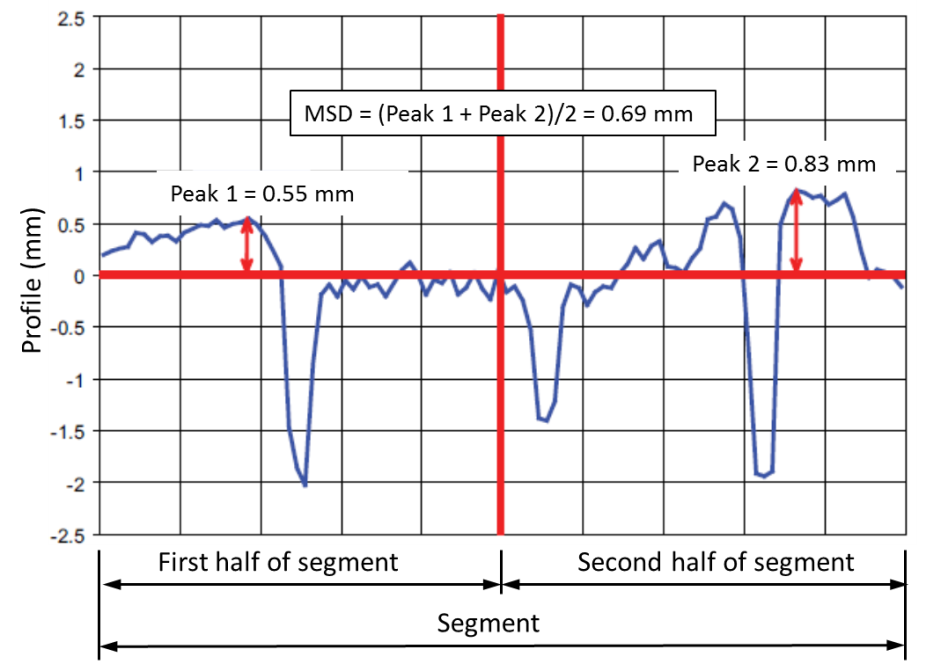

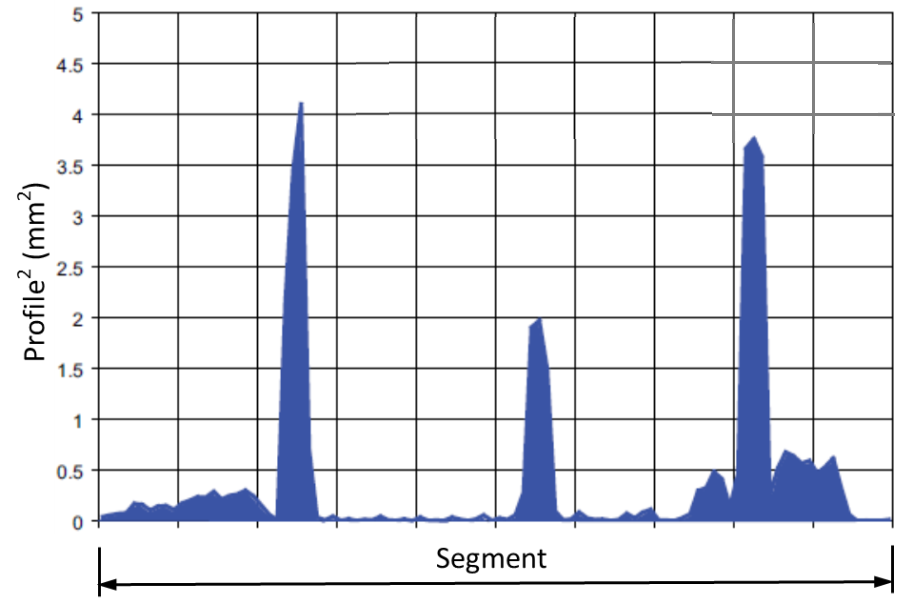

Computer software can process the data to report either the MPD (in accordance with ASTM E1845) or the RMS.(7) For each test site, invalid readings caused by deep surface troughs or local photometric properties of the surface are eliminated when their value is higher or lower than the profile range for nearby locations. The invalid value for a location is replaced with one interpolated from the values at the previous and next locations. Highfrequency components that correspond to texture wavelengths less than 2.5 mm (0.098 inches) are removed to reduce the influence of noise and transients, leading to a relatively uniform influence of narrow profile peaks. For each segment, a linear regression of the estimated profile values is performed. The regression line is subtracted from the profile values of the segment to translate the data to a 0 mean. Each segment is further divided into two subsegments with equal lengths, and the maximum value of the profile is determined for each subsegment. These two values are averaged to obtain the MSD (figure 4). The average of the MSD values for all eight segments represents the MPD. Figure 5 illustrates the calculation of the RMS of each segment of the profile in figure 4.

© 2011 The Transtec Group, Inc. 1 mm = 0.039 inches.

© 2011 The Transtec Group, Inc. 1 mm = 0.039 inches.  © 2011 The Transtec Group, Inc. 1 mm = 0.039 inches.

© 2011 The Transtec Group, Inc. 1 mm = 0.039 inches. Data Interpretation

Comparison of MPD and RMS values for a surface provides information on the nature of the texture. Profiles from individual segments can be used to examine the surface texture in different directions (e.g., parallel or perpendicular to the direction of travel). Figure 6 shows pavement texture categories and their effects on surface characteristics. Large MPD and/or RMS values indicate coarse macrotexture, which is good for wet weather friction and traffic noise (airpumping noise) but will cause more tire wear, traffic noise (tire–pavement noise), and rolling resistance.

© 2013 The Transtec Group, Inc. 1 µm = 0.039 mils; 1 mm = 0.039 inches; 1 m = 3.3 ft. PIARC = World Road Association.

© 2013 The Transtec Group, Inc. 1 µm = 0.039 mils; 1 mm = 0.039 inches; 1 m = 3.3 ft. PIARC = World Road Association. Advantages

Measuring surface texture with a circular texture meter has the following advantages:(5)

- Results are repeatable and reproducible.

- MPD correlates well with MTD.

- Positive and negative textures are measurable.

- Equipment is portable.

- Setup time is short.

Limitations

Measuring surface texture with a circular texture meter has the following limitations:(5)

- The method is slow and requires lane closure.

- Each test result only represents a small surface area.

- Results do not reflect full-scale tire behavior.

References

- World Road Association (PIARC). (1987). Report of the Committee on Surface Characteristics, XVIII World Road Congress, Brussels, Belgium.

- Hanson, D.I. and Prowell, B.D. (2004). Evaluation of Circular Texture Meter for Measuring Surface Texture of Pavements, Report No. 04-05, National Center for Asphalt Technology, Auburn University, Auburn, AL.

- Stroup-Gardiner, M. and Brown, E.R. (2000). Segregation in Hot-Mix Asphalt Pavements, Report No. 441, Transportation Research Board, Washington, DC.

- Merritt, D.K., Lyon, C.A., and Persaud, B.N. (2013). Evaluation of Pavement Safety Performance, Report No. FHWA-HRT-14-065, Federal Highway Administration, Washington, DC.

- National Cooperative Highway Research Program. (2009). Guide for Pavement Friction, Web-Only Document 108, Transportation Research Board, Washington, DC.

- ASTM E2157-15. (2015). “Standard Test Method for Measuring Pavement Macrotexture Properties Using the Circular Track Meter.” Book of Standards 04.03, ASTM International, West Conshohocken, PA.

- ASTM E1845-15. (2015). “Standard Practice for Calculating Pavement Macrotexture Mean Profile Depth.” Book of Standards 04.03, ASTM International, West Conshohocken, PA.

- Rasmussen, R.O., Sohaney, R., Wiegand, R., and Harrington, D. (2011). Measuring and Analyzing Pavement Texture, National Concrete Pavement Technology Center, Ames, IA.