Pavements - Sounding

Target of Investigation

Sounding is a common method used to survey concrete surfaces for areas of delamination and for structural evaluation and repair.(1) Typically, chain drags are used to determine the general locations of debonding and delaminated areas, and hammer sounding is performed to determine the extent of debonding and delamination in each area.(2) Chain drags are limited to horizontal surfaces, while hammer sounding can be employed on a range of structures.(3) Sounding generally cannot be used on asphalt pavement and should not be used on frozen concrete.(4)

Description

The typical chain drag configuration consists of four or five approximately 18-inch (45-cm) segments of 1-inch (2.54-cm) link chain with 0.25inch (6.35-mm) diameter steel attached to a 2ft (0.6-m) piece of aluminum or copper tube. A 2- to 3-ft (0.6- to 0.9-m) handle is attached to the tube to form a T shape.(4) The operator drags the chain across the concrete surface to listen for delaminated areas. The impact will produce a clear ring on sound concrete and a dull, hollow sound on delaminated, disbanded, or softened concrete.(5) A steel rod or ball-peen hammer can also be used, but these are better suited for smaller areas or defining the extent of a delamination after an area has been located using a chain drag. A chain drag survey provides a low-cost inspection of delaminated areas in a concrete surface but is subjective and requires an experienced inspector.(5) Additionally, high levels of environmental noise, such as from an active road, may interfere with the operator’s ability to hear pavement responses.(4)

Physical Principle

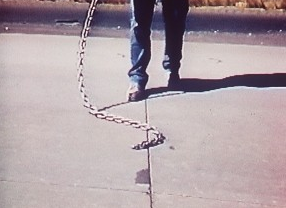

Chain dragging is an elastic-wave test in which the operator drags a chain on a surface and listens for the sound the chain makes (figure 1 and figure 2). The presence of delamination changes the audible frequencies of the surface response. A hollow sound results from flexural oscillations in the delaminated concrete that create a drumlike effect, typically in the 1- to 3-kHz range, which is within the audible range of the human ear.(3) Chain drags can only detect significant delaminations and cannot detect early signs of delamination or deep delaminations.(6) The principle is the same for sounding with a steel rod or hammer (figure 3 and figure 4).

Source: FHWA.

Source: FHWA.  Source: FHWA.

Source: FHWA. Source: FHWA.

Source: FHWA.  Source: FHWA.

Source: FHWA.Data Collection

To perform a sounding evaluation using chain drag on concrete pavements, refer to the procedure for testing concrete bridge decks, which is introduced in ASTM D4580/D4580M-12, Standard Practice for Measuring Delaminations in Concrete Bridge Decks by Sounding.(4) The process, in general, can be described by the following steps:

- Remove any accumulated debris from the pavement surface.

- Construct a grid system on the surface to easily plot delaminated areas.

- Drag chains over the surface, listening for dull or hollow sounds indicating delaminated concrete.

- Outline areas of delamination on the surface with spray paint or a lumber crayon (figure 5).

Source: FHWA.

Source: FHWA. Chain dragging is a relatively fast method for determining the approximate location of delamination, and hammer sounding is a slow but accurate method to determine the boundaries of a delaminated area.(3)

Data Processing

No data are processed, but a map of the delaminated areas is prepared via the grid applied to the concrete surface.(4)

Data Interpretation

Marked areas of delamination can be used for further evaluation of the structure or the removal and repair of the damaged areas.(1)

Advantages

Advantages of chain dragging include the following:

- Accurate in detecting moderate to severe concrete delamination.

- Well established.

- Low cost and relatively rapid.

- Simple procedures for data collection and mapping.

- Effective for initial surveys and repairs.

Limitations

Limitations of chain dragging include the following:

- Subjective.

- Requires experienced operator.

- Requires traffic control.

- Inconsistent performance.

- Cannot detect early or deep delaminations.

- Ineffective on asphalt pavement and asphalt overlays.

References

- Federal Highway Administration. (2015). “Partial Depth Repairs.” (website) Washington, DC. Available online: www.fhwa.dot.gov/pavement/concrete/repair00.cfm, last accessed April 5, 2016.

- Boyd, S.R. and Frauss, P.D. (2006) Highway Concrete Technology Development and Testing: Volume V – Field Evaluation of Strategic Highway Research Program (SHRP) C-206 Test Sites (Bridge Deck Overlays), Report No. FHWA-DR-02-086, Federal Highway Administration, Washington, DC.

- Gucunski, N., Imani, A., Romero, F., Nazarian, S., Yuan, D., Wiggenhauser, H., Shokouhi, P., Taffee, A., and Kutrubes, D. (2013). Nondestructive Testing to Identify Concrete Bridge Deck Deterioration, Report No. S2-R06A-RR-1, Transportation Research Board, Washington, DC.

- ASTM D4580/D4580M-12. (2012). “Standard Practice for Measuring Delaminations in Concrete Bridge Decks by Sounding.” Book of Standards 04.03, ASTM International, West Conshohocken, PA.

- Boyd, A.J., Birgisson, B., Ferraro, C., and Cumming, S. (2005). Nondestructive Testing for Advanced Monitoring and Evaluation of Damage in Concrete Materials, Florida Department of Transportation, Tallahassee, FL.

- Gucunski, N., Romero, F., Kruschwitz, S., Feldmann, R., and Parvardeh, H. (2011). Comprehensive Bridge Deck Deterioration Mapping of Nine Bridges by Nondestructive Evaluation Technologies, Report No. SPR-NDEB(90)—8H-00, Iowa Department of Transportation, Ames, IA.