Pavements - Galvanostatic Pulse Measurement (GPM)

Target of Investigation

The galvanostatic pulse method can be used on new and existing reinforced concrete pavements to estimate steel reinforcement’s corrosion rate, which cannot be determined by similar electrochemical methods, such as electrical resistivity (ER) or half-cell potential (HCP) testing. The galvanostatic pulse method can also be used to determine the ER of the concrete.

Description

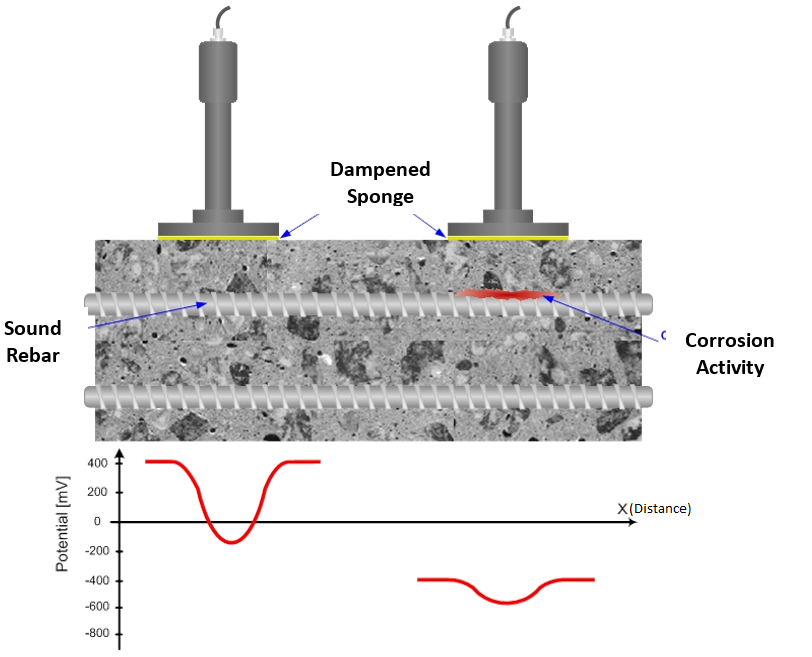

The galvanostatic pulse method is a nondestructive electrochemical method for the rapid assessment of rebar corrosion in reinforced concrete structures.(1) It is an active method that polarizes the reinforcing steel through the induction of short current pulses and measures the resulting changes of electrochemical potential.(2) The system is connected electrically to the reinforcing steel of the concrete pavement. A counter electrode and a reference electrode are placed on the concrete surface. The counter electrode galvanostatically imposes a short anodic current pulse on the reinforcement. This current results in a change of reinforcement potential, which is measured by the system. These measurements are used to calculate the HCP, rate of corrosion, and resistance between the steel reinforcement and the system.

A typical galvanostatic pulse system includes the following (figure 1):

- Handheld computer with data acquisition software.

- Calibration unit for pulse generator.

- Reference and counter electrodes.

- Wet sponges.

- Lead cables and connectors.

Figure 1. Photo. Galvanostatic pulse system in operation.(1)

Physical Principle

The galvanostatic pulse method measures the current required to change the difference in potential between the steel reinforcement in the concrete pavement and the reference electrode of the system. Actively corroding steel reinforcement within concrete induces a flow of electrons between anodic and cathodic sites. An anodic site forms on the steel when metal ions pass into an electrolytically conducting liquid, leaving excess electrons on the base metal. These electrons flow to a cathodic site in the concrete where oxidizing agents in the liquid consume them, thus inducing a current between the anode and cathode.(1) Measuring the current and voltage allows an inspector to determine polarization resistance, which is related to corrosion rate.

The galvanostatic pulse method uses a counter electrode placed on the concrete surface, impressing an anodic current pulse, usually in the range of 5–400 μA, into the reinforcement.(3) The first pulse is strong and typically has a duration of 3–60 s. The pulse amplitude can be adjusted according to the properties of the concrete under investigation. Several short, consecutive pulses of gradually increasing intensity may follow the first until a sufficiently high polarization of the steel reinforcement is achieved. The applied current polarizes the steel anodically with respect to the free corrosion potential. This change of reinforcement potential is recorded as a function of polarization time by the reference electrode.(3) Noncorroding (passive) steel reinforcement possesses no current and has a high resistance to current flow, reflected in a potential shift of around 100 mV. Actively corroding steel reinforcement features a current between the anode and cathode and has a low resistance to current flow, reflected in a lower shift in potential compared to a passive site (figure 2).(1)

Figure 2. Composite graph. Principle of the galvanostatic pulse method.(1)

Data Acquisition

For data collection using the galvanostatic pulse method on concrete pavement, follow the procedure described in ASTM C876-09, Standard Test Method for Corrosion Potentials of Uncoated Reinforcing Steel in Concrete. The procedure is summarized as follows:(4)

- Identify points or lay out a grid for data collection on the pavement, ensuring that points are not so close together that measurements overlap and are not so far apart that localized corrosion is missed.

- Electrically connect the reinforcing steel to the positive lead of the system (figure 3). The following are typical steps to accomplish this procedure:

- Locate the steel using a rebar locator, drill down to the reinforcement, and connect a lead wire to the steel using a self-tapping screw drilled into the rebar.

- Ensure all measurement locations are electrically continuous with this tap.

- Confirm that the entire survey area is covered; this may require multiple taps and corresponding measurement areas.

- Electrically connect the reference electrode to the negative lead of the system.

- Wet the contact sponge of the reference and counter electrodes to ensure good electrical contact with the concrete pavement; prewetting can also be used if conditions allow. The following steps describe the prewetting process:

- Wet the entire surface of the testing locations but make sure no free surface water remains between test locations before taking measurements.

- Place a prewetted sponge on each test location before taking measurements and leave it in place for the duration of collection at that location.

- Place the reference electrode on the test point (figure 4).

- Adjust the current pulse amplitude with one strong and then several shorter pulses until the reinforcing steel reaches a sufficiently high polarization.

- Record the potential variations using a handheld computer with data acquisition software.

- Move to the next test point and repeat the collection procedure.

- After testing is completed, patch all tap locations.

Figure 3. Photo. Electrical connection to exposed reinforcement steel.(1)

Figure 4. Photo. Data collection with galvanostatic pulse system.

Data Processing

Typically, no processing is performed for data collected using the galvanostatic pulse method. The system usually has contour-mapping software for gridding and plotting data for visualization purposes. The slope of the potential–time curve measured during the current pulse can be used to provide information about the corrosion state of the steel reinforcement, and the potential data can be used to obtain a measure of the concrete ER for a given concrete cover depth.

Data Interpretation

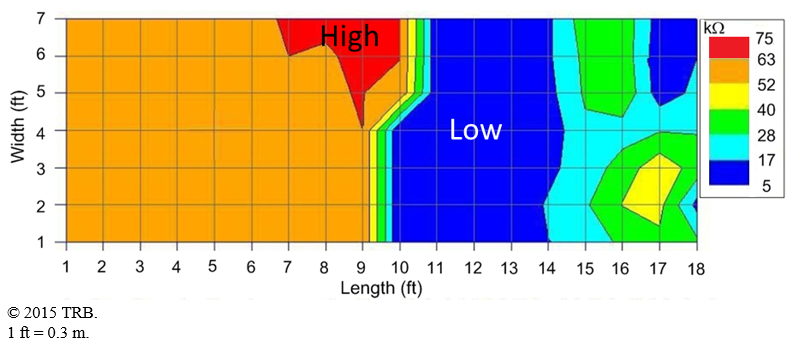

Figure 5 and figure 6 are typical contour maps from a galvanostatic pulse method survey. Figure 5 is an ER map that shows values ranging from 5 to 63 kΩ. Areas with lower ER values indicate a higher probability of a corrosive environment from the intrusion of moisture, chlorides, and salts in the concrete. Areas with higher ER values indicate a noncorrosive environment.

1 ft = 0.3 m.

Figure 5. Contour map. Concrete ER from a galvanostatic pulse method survey.(5)

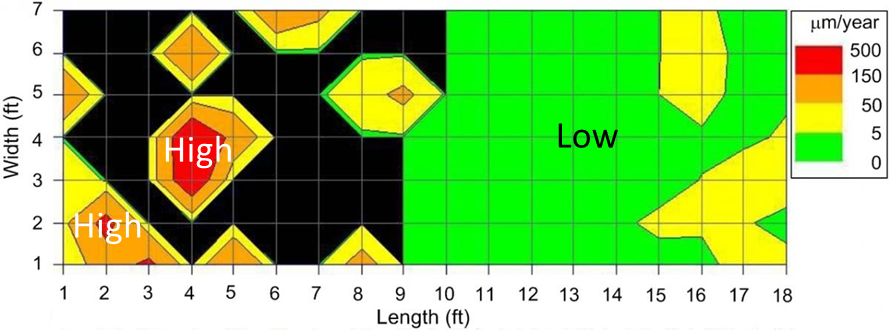

From the corrosion rate, cross section loss can be estimated using Faraday’s law of electrochemical equivalent. Figure 6 shows cross section loss assuming that a corrosion rate of 1 μA/cm2 (6.45 μA/inch2) corresponds to a cross section loss of about 11.6 μm/yr (0.457 mils/yr) for carbon steel.

1 ft = 0.3 m; 1 μm = 0.039 mils.

Note: Black indicates no data for those areas.

Figure 6. Contour map. Estimated section loss based on corrosion rates from a galvanostatic pulse method survey.(5)

The obtained corrosion rate is an instantaneous average value. A more detailed knowledge of the daily and seasonal changes in the corrosion rate is required to obtain lifetime predictions of service life and condition. The data obtained from the galvanostatic pulse method survey should be combined with data from other nondestructive tests and other investigations to determine concrete integrity and penetration rates.(1)

Advantages

Advantages of the galvanostatic pulse method include the following:

- Calculates reinforcement steel corrosion rates.

- Obtains HCP and ER measurements.

- Requires low to medium level of expertise to operate data collection equipment.

- Does not require much data processing.

Limitations

Limitations of the galvanostatic pulse method include the following:

- Requires electrical connectivity to reinforcing steel throughout test area.

- Gives unstable measurements when ER of the concrete cover is high.(1)

- Requires a few minutes for stabilization of potential before measurements can be recorded.(1)

- Is time consuming and labor intensive for large survey areas.

- Cannot be used with epoxy-coated reinforcing steel.(4)

References

- Gucunski, N., Imani, A., Romero, F., Nazarian, S., Yuan, D., Wiggenhauser, H., Shokouhi, P., Taffee, A., and Kutrubes, D. (2013). Nondestructive Testing to Identify Concrete Bridge Deck Deterioration, Report No. S2-R06A-RR-1, Transportation Research Board, Washington, DC.

- Federal Highway Administration. (2016). “Nondestructive Evaluation Laboratory: Equipment.” (website) Washington, DC. Available online: https://highways.dot.gov/laboratories/nondestructive-evaluation-laboratory/laboratory-equipment, last accessed April 10, 2016.

- Germann Instruments. (n.d.) “All products.” (website) Evanston, IL. Available online: http://germann.org/all-products, last accessed March 5, 2019.

- ASTM C876-015 (2015). “Standard Test Method for Corrosion Potentials of Uncoated Reinforcing Steel in Concrete.” Book of Standards 03.02, ASTM International, West Conshohocken, PA.

- Strategic Highway Research Program. (n.d.) “SHRP2 NDToolbox.” (website) Washington, DC. Available online: https://www.fhwa.dot.gov/goshrp2/Solutions/Operations/R06/NDToolbox, last accessed September 11, 2019.