Tunnel - Electrical Resistivity (ER)

Target of Investigation

Electrical resistivity (ER) testing is used to characterize the corrosive environment of reinforced concrete members in tunnels. It is primarily employed to identify reinforced concrete sections that are susceptible to corrosion from water and chloride penetration.(1) For corrosion assessment, ER testing can also be used to complement other nondestructive evaluation surveys, such as halfcell potential (HCP), which describes the probability of corrosion activity.(2,3)

Description

By measuring concrete surface ER, this testing method is effective for assessing the susceptibility of reinforced concrete to a corrosive environment.(4) The presence and concentration of water and chlorides are important parameters when characterizing a corrosive environment for reinforced concrete.(1) Damaged and cracked areas become preferential paths for fluid and ion flow, creating an environment that is conducive to corrosion. This environment allows a current to pass between anodic and cathodic sites on the steel reinforcement. The higher the ER of the concrete, the lower this current will be.(1) Low ER values indicate an environment that supports corrosion and typically leads to high corrosion rates.(4)

The ER testing system usually consists of a four-electrode Wenner probe (figure 1). A measurement is taken by pressing the probe against a damp concrete surface. The probe or an attached device such as a tablet, displays the ER, which is recorded by the tester.(4)

A. Top view.

B. Side view.

Figure 1. Photos. Four-point Wenner probe.

Physical Principle

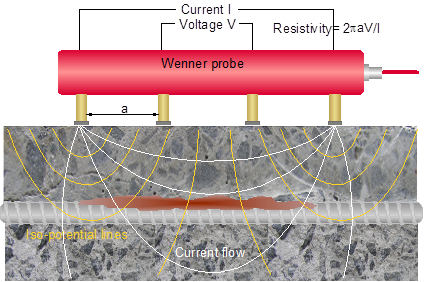

ER and its reciprocal, electrical conductivity, are properties that quantify a material’s ability to oppose and conduct an electric current, respectively. ER is measured in units of kilohmcentimeter (kΩ-cm). Electrical conduction in concrete systems is primarily because of electrolytic current flow through the open-pore system between the anodic and cathodic sites on the reinforcement, where damaged and cracked areas become preferential paths for fluid and ion flow.(5) The surface ER measurements of a steel-reinforced concrete structure can be used to characterize the corrosive environment of the concrete. The voltage and current are measured at the surface of the concrete using a Wenner probe (figure 2).(1) Four equally spaced electrodes are galvanically connected to the concrete using wet sponges on each electrode. A current is applied through the concrete between the two outer electrodes, and the potential of the generated electrical field is measured between the two inner electrodes. The ER is then calculated using the equation in figure 3.

Figure 3. Illustration. Physical principle of ER testing.(1)

- Where:

- ρ = ER (kΩ-cm).

- a = distance between electrodes (cm).

- V = voltage (V).

- I = current (A).

In general, low ER measurements indicate areas where the environment is conducive to corrosion, while high ER measurements indicate areas where the environment does not facilitate corrosion. The correlation between ER values and corrosion rates of concrete is given in table 1.

Table 1. Correlation between ER values and corrosion rates in concrete.(3)

| ER (kΩ-cm) | Corrosion Rate |

| Less than 5 | Very high |

| 5 to 10 | High |

| 10 to 20 | Moderate to low |

| Greater than 20 | Low |

1 kΩ-cm = 0.39 Ω-inch.

Building materials—such as concrete, cement, and wood—are ion conductors, which means electrical conduction occurs through the interconnected pore spaces. Dry concrete has a high ER that impedes current flow between the anodic and cathodic sites on corroded steel reinforcement, while highly permeable and moist concrete has a low ER and is conductive to the corrosion current. The ER of fully saturated concrete is approximately 10–100 kΩ-cm (3.93–39.37 Ωinches), depending on the conductivity of the saturating fluid. When concrete is oven dried, its ER can be higher than 100 kΩ-cm (39.37 Ω-inches), causing it to act as an insulator.(1) Since concrete is a composite material, its ER depends on its porosity, pore-size distribution, cement chemistry, water-to-cement ratio, presence of admixtures, ion type, saturation fluid, and other factors. Field ER measurements can be affected by the concrete’s surface-level moisture, carbonation, and any steel reinforcement in the vicinity of the electrodes.(6–8)

Data Acquisition

Currently, no ASTM standard exists for using a Wenner probe to measure the ER of a surface of a reinforced concrete structure. ASTM G57-06, Standard Test Method for Field Measurement of Soil Resistivity Using the Wenner Four-Electrode Method, can serve as a guideline, but differences prevail between concrete and soil applications.(9) The typical procedure for data collection on a reinforced concrete surface is as follows:

- Identify testing locations of interest or lay out a grid for data collection on the tunnel surface.

- Ensure a galvanic connection between probe electrodes and the concrete surface by taking the following steps:

- Prewet each test location, if the concrete surface is dry.

- Use water, contact graphite gel, or pastes.

- Do not overwet the surface; too much moisture may contribute to probe-to-probe current flow along the surface.(5)

- Keep sponges on the ends of the probe electrodes wet.

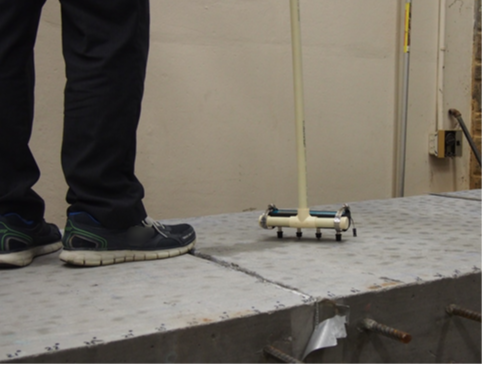

- Place the Wenner probe against the surface with the center of the probe oriented at the test location (figure 4).

- Record the measured ER value.

- This procedure is repeated for each test location.

Figure 5. Photo. Fully integrated four-point Wenner probe in place at the test location.

Data Processing

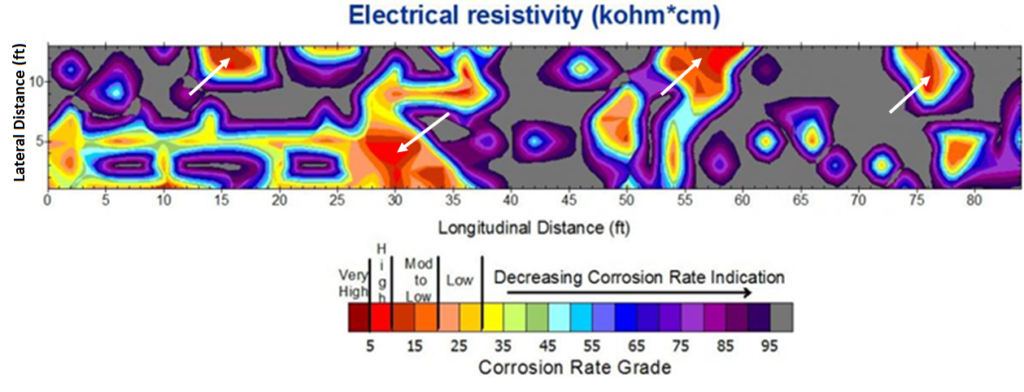

Data processing is not complicated and consists mostly of plotting raw data.(1) This generally produces a contour map of the measured ER displayed with the spatial distribution of the test locations (figure 5).

Data Interpretation

Data interpretation can be challenging because the ER of the concrete depends on several material properties, including moisture content, salt content, and porosity. The delineation of each property’s specific contribution to the whole is difficult.(1) The tester uses the ER data to determine the overall susceptibility of the specimen to corrosion.

1 ft = 0.3 m; 1 kΩ-cm = 0.39 Ω-inch.

Note: Arrows indicate areas with very low ER.

Figure 6. Contour map. Plotted ER measurements.(1)

Advantages

Advantages to ER testing include the following:

- Easy-to-use system that requires little training.(5)

- Straightforward data processing.

- Reliable, precise, and accurate measurements.(5)

- Robust and relatively inexpensive system.(5)

- Complementary to HCP surveys.

Limitations

Limitations to ER testing include the following:

- Cannot directly measure the corrosion rate; can only characterize a corrosive environment.

- Requires complex data interpretation to mitigate multiple contributing factors affecting the ER value.

- Can produce inaccurate values because of overwetting during testing, which can lead to probe-to-probe current flow along the surface.

- Cannot be used when electrically isolating layers are present on the surface.

References

- Gucunski, N., Imani, A., Romero, F., Nazarian, S., Yuan, D., Wiggenhauser, H., Shokouhi, P., Taffee, A., and Kutrubes, D. (2013). Nondestructive Testing to Identify Concrete Bridge Deck Deterioration, Report No. S2-R06A-RR-1, Transportation Research Board, Washington, DC.

- Gowers, K.R. and Millard, S.G. (1991). “The Effect of Steel Reinforcement Bars on the Measurement of Concrete Resistivity.” British Journal of Non-Destructive Testing, 33(11), pp. 551–554, British Institute of Non-destructive Testing, Southend-on-Sea, United Kingdom.

- Gowers, K.R. and Millard, S.G., (1999). “Measurement of Concrete Resistivity for Assessment of Corrosion Severity of Steel Using Wenner Technique.” ACI Materials Journal, 96(5), pp. 536–542, American Concrete Institute, Farmington Hills, MI.

- Federal Highway Administration. (2016). “Nondestructive Evaluation Laboratory: Equipment.” (website) FHWA, Washington, DC. Available online: https://highways.dot.gov/laboratories/nondestructive-evaluation-laboratory/nondestructive-evaluation-laboratory-overview, last accessed April 18, 2016.

- Gucunski, N., Romero, F., Kruschwitz, S., Feldmann, R., and Parvardeh, H. (2011). Comprehensive Bridge Deck Deterioration Mapping of Nine Bridges by Nondestructive Evaluation Technologies, Report No. SPR-NDEB(90)—8H-00, Federal Highway Administration, Washington, DC. Available online: https://www.iowadot.gov/bridge/ndt_projects/IowaDOT_Final_NDT_Report.pdf, last accessed October 7, 2019.

- Kruschwitz, S. (2007). Assessment of the Complex Resistivity Behavior of Salt Affected Building Materials, Ph.D. Thesis, Technical University, Berlin, Germany.

- Hunkeler, F. (1996). “The Resistivity of Pore Water Solution – A Decisive Parameter of Rebar Corrosion and Repair Methods.” Construction and Building Materials, 10(5), pp. 381–389, Elsevier, Amsterdam, Netherlands.

- Burchler, D., Elsener, B., and Bohni, H. (1996). “Electrical Resistivity and Dielectric Properties of Hardened Cement Paste and Mortar.” Electrically-Based Microstructural Characterization, 411, pp. 407–412, Materials Research Society, Warrendale, PA.

- ASTM G57-06. (2009). “Standard Test Method for Field Measurement of Soil Resistivity Using the Wenner Four-Electrode Method.” Book of Standards 03.02, ASTM International, West Conshohocken, PA.