Bridge - Phased Array Ultrasonic Testing (PAUT)

Target of Investigation

PAUT can be applied to detect cracks and weld flaws in steel bridge members. The technology is typically implemented using longitudinal (straight beam) or shear wave (angled beam) methods.

Longitudinal wave methods are used to test surfaces not available for visual assessment, such as detecting cracks in bridge pins, trunnion shafts, or eyebars. Longitudinal wave methods may also be used for measuring the thickness of a steel plate to detect section loss or for imaging corrosion pits.

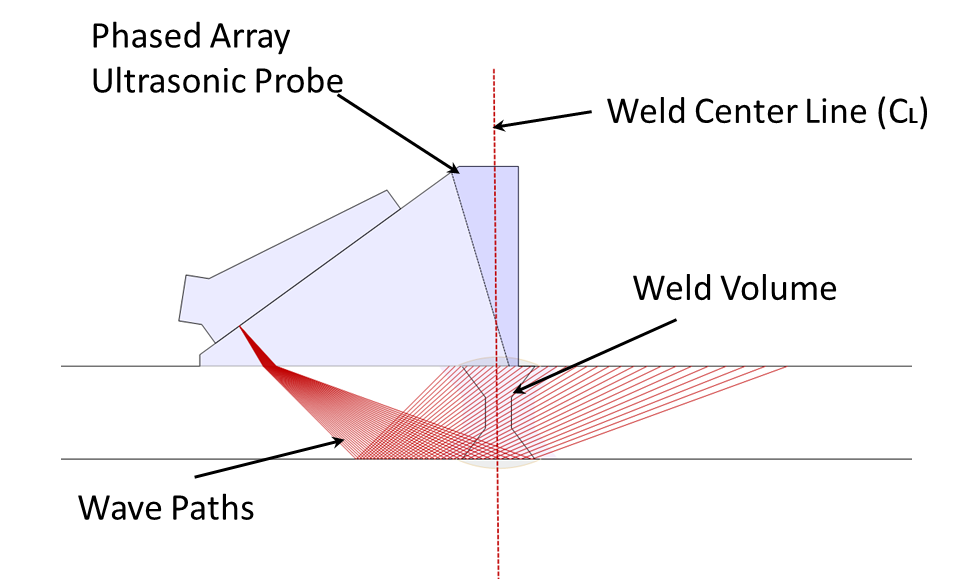

Shear wave methods (angled beam) are commonly used to inspect welds for flaws (figure 1).

Description

PAUT is a nondestructive evaluation technology used to detect defects such as cracks and weld flaws in steel bridge components. The technology uses acoustic waves launched from a transducer which propagate through the material and are reflected from discontinuities in the material. The reflected waves are detected by the transducer and analyzed. PAUT transducers are comprised of a number of sensor elements that generate and detect acoustic waves. Each individual element in the transducer launches an acoustic wave which combines in the material being tested to allow the resulting ultrasonic beam to be steered in different directions or focused at different depths. The ability to steer the ultrasonic beam in different directions increases the volume of material insonified from a single transducer position. This allows the technology to direct acoustic energy toward a particular location in the material being tested, allowing the wave beam to be scanned across the area where cracking is likely to initiate The beam steering capabilities of PAUT also provide full volumetric coverage of difficult to access areas.

Physical Principle

PAUT detects defects using the same physical principles as conventional UT, launching an acoustic wave from a transducer and analyzing reflections from discontinuities and the physical boundaries of the material being tested. Conventional UT launches waves from a single element and receives (detects) waves using a single element. In contrast to conventional UT, PAUT uses multiple sensor elements to launch and receive acoustic waves. The physical principle of wave interference is used to combine waves launched from the individual sensors to form a beam of acoustic energy that propagates in a desired direction. This allows the wave beam direction to be controlled and “steered” in a desired direction or focused at a desired distance from a PAUT transducer.

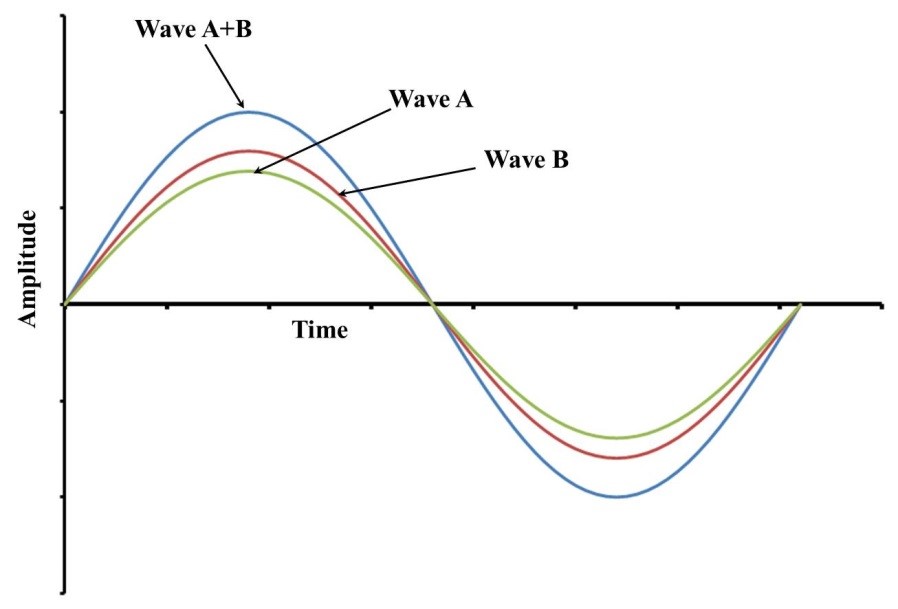

Wave interference occurs when two or more acoustic waves occupy the same space at the same point in time. Figure 2 illustrates the effect of constructive interference on the amplitude of an acoustic wave. If wave A and wave B occupy the same space and are in phase as shown in the figure, these individual waves will combine to form a wave with an amplitude equal to the sum of the two individual wave amplitudes. This phenomenon is known as constructive interference. PAUT utilizes this phenomenon by launching waves from several individual sensor elements at different points in time, so the interference between the individual waves results in a plane wave propagating in a certain direction within the material being tested.(1)

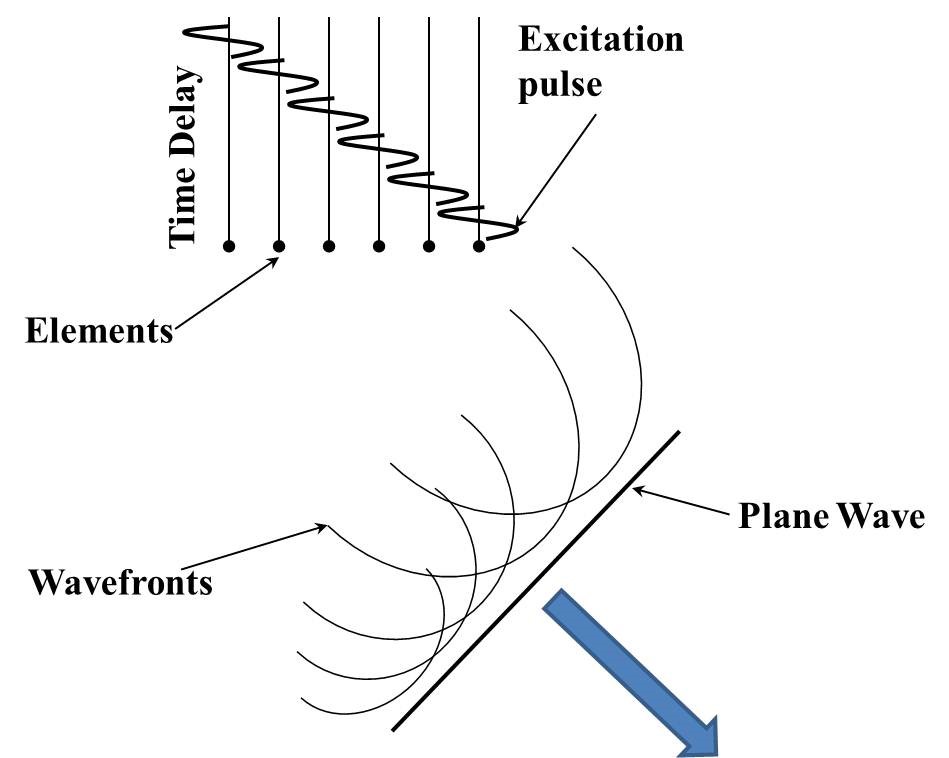

Figure 3 illustrates the wave interference phenomenon used to control the direction of an acoustic wave beam launched from a series of individual sensor elements. In the figure, the sensor elements are represented as point sources for acoustic waves. Acoustic waves are launched from each individual sensor as the result of an excitation pulse. These excitation pulses are delayed in time (i.e., phased) to result in constructive interference of the individual waves within the material. In this manner, the acoustic wavefront can be “steered” or focused at a particular depth into the material by modifying the delay between the pulses from the individual sensors.

Data Acquisition

PAUT utilizes transducers comprised of multiple sensor elements that launch and receive acoustic waves in the material being tested. Pulser circuitry in the instrument controls electronic pulses so individual sensors are excited at different points in time to transmit acoustic waves into the material being tested. This allows the shape and direction of the resulting beam of acoustic energy to be controlled so the beam may be steered at different angles or focused at different depths in the materials. Receiver circuitry in the instrument applies electronic delay to each sensor element to match the beam shape formed by the pulser. The received waveforms from each sensor may be combined into a single acoustic signal. This signal is digitized and stored in the computer.

Figure 4 shows a photograph of a typical PAUT instrument being used in the field (bottom). The battery-operated instrument contains the pulser-reciever circuitry and supporting software necessary to achieve beam forming, detect and store resulting waveforms, and produce different presentations of the data. A typical phased array transducer (top) attached to a refracting wedge that allows for angled beam testing using shear waves.

Data Processing

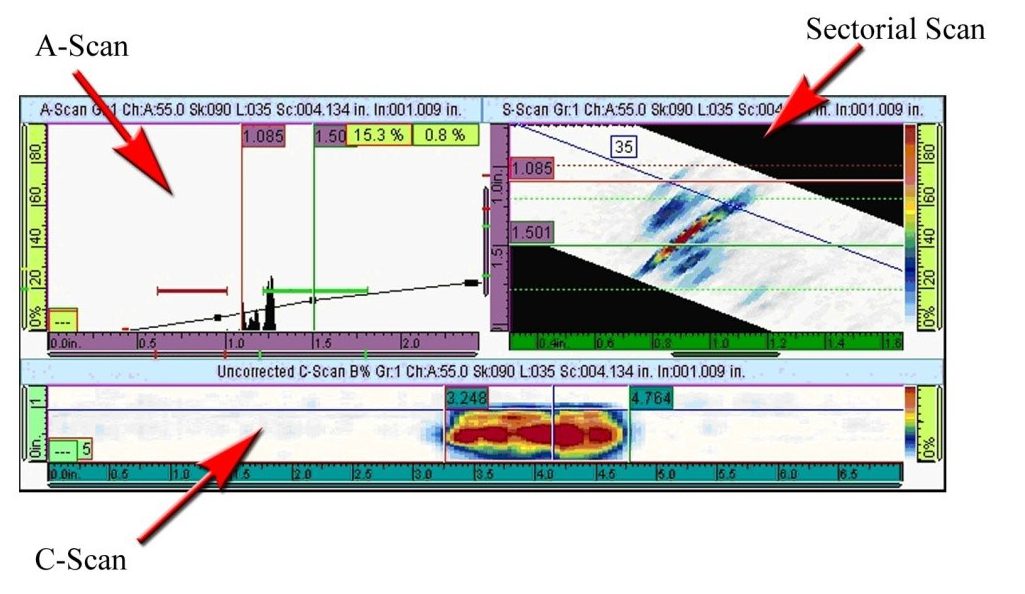

Waveforms received by the transducer are digitized and stored. These data are presented in a variety of formats for interpretation by the operator. Common presentations include A-scans, displaying a single waveform, and sectorial scans, displaying the results of multiple waveforms combined to form a color-coded image.

The A-scan display shown in figure 5 presents waveform amplitude versus time, the typical data presentation for conventional ultrasonic pulse-echo technologies.

A sectorial scan displays a color representation of wave amplitudes detected by the transducer. The display is formed from the combination of numerous A-scans captured as the beam is steered at different angles. To form the sectorial scan, the amplitude of each data point in an A-scan is assigned a color from a defined color palette (shown to the right of the sectorial scan in figure 5). The color representation of the amplitude of each individual A-scan produced as the wave beam is steered through the desired angles is then plotted. Using this graphical representation, indications that cause high amplitude reflections as the wave beam is steered through the desired angles appear as two-dimensional features on the sectorial scan. Data may also be presented in a C-scan format when a two-dimensional scanner is used to scan the transducer across the surface of the material being tested. The C-scan format presents the linear ordinate of the transducer on the x-axis and the color-coded amplitude of the A-scans across the transducer aperture plotted on the vertical axis. A spatial image showing areas of section loss and/or deep corrosion pits is produced.

Data Interpretation

Data is interpreted in the same manner for PAUT as for conventional pulse-echo UT. The amplitude of reflected waves is compared with a standard to assess if a given indication is acceptable or unacceptable. If a linear encoder is used during the data collection process, the length of indications may be estimated based on the data collected and stored.

Advantages

- Can detect both surface and subsurface flaws.

- Can assess areas that are inaccessible for visual inspection.

- Improved volumetric coverage and greater flexibility for testing complex geometries.

- Complete data records stored for future reference.

Limitations

- Requires surface preparation.

- Requires well-trained and experienced operators.

- Increased cost of equipment as compared to conventional UT.

References

- Olympus NDT, Inc. (2007). Advances in Phased Array Ultrasonic Technology Applications, Waltham, MA.